Table of contents:

Application scenario

Structure and operation and maintenance

Technical standard

Selection key

Reference materials

Ⅰ. Application scenario:

The essential difference between downhole pumps and drilling pumps begins with the differentiation of application fields.Drilling pumps are mainly used in clear water extraction scenarios such as agricultural irrigation and industrial water supply. They are suitable for drilling environments with 3-48-inch aperture. The 4-18-inch model is the mainstream of the market. The core of its design is to adapt to narrow drilling space and medium delivery efficiency.The downhole pump focuses on oil, natural gas and other energy extraction, and needs to withstand high temperature, high pressure, and complex media containing sand and gas. For example, Tieling Dongsheng's API Type Rod pump can be designed according to the buyer's applicable oil well environment.

Ⅱ. Structure and operation and maintenance:

Structural differences:

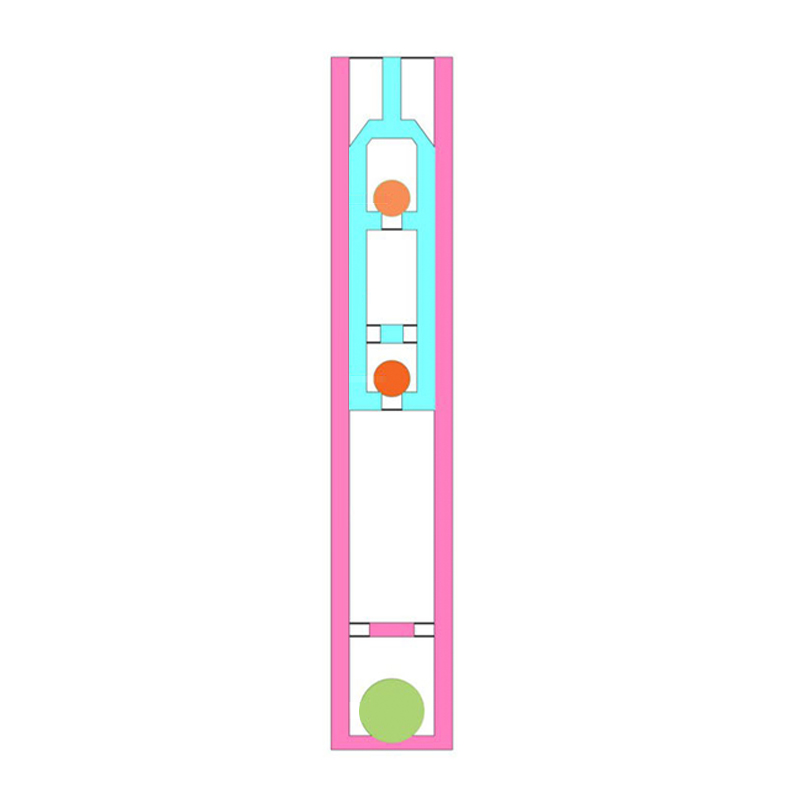

The drilling pump adopts a modular structure with the upper and lower layout of the motor and the pump body, and the impeller is dynamically balanced to reduce vibration. The material covers conventional materials such as cast iron and stainless steel 316; the API Type Rod pump adopts the plug-in structure of “internal and external working cylinder + plunger”, which is divided into various types such as fixed at the top of the fixed cylinder and fixed at the bottom of the fixed cylinder. The chrome-plated thickness of the pump cylinder is ≥0.076mm, and the thickness of the plunger spray welding layer is over 0.25mm, which is resistant to harsh underground working conditions.

Operation and maintenance efficiency:

Due to the limited sinking depth of the motor, the drilling pump needs to be hoisted as a whole for maintenance and is suitable for shallow operations; the API Type Rod pump inspection pump does not need to lift the oil outlet pipe, and the maintenance can be completed only by lifting the oil pumping rod, and the single well operation time is shortened by more than 40%, especially suitable for deep wells above 2500 meters.Tieling Dongsheng's API Type Rod Pump is also equipped with a blowout preventer assembly to reduce the risk of high-pressure well operations.

Ⅲ. Technical standard:

The standardization requirements for pump products in petroleum extraction far exceed that of ordinary drilling pumps.Tieling Dongsheng's API Type Rod Pump strictly follows the API 11AX specification and the ISO9001 system, and has obtained the API monogram license of the American Petroleum Administration. Its Verne seat is made of 6Cr18Mo material with a hardness of HRC52-56. The Verne ball uses 9Cr18Mo, which has been verified by vacuum sealing tests and is suitable for complex well conditions such as sand and corrosion.On the other hand, drilling pumps, although there are material customization options, there is no unified special standard for the energy industry.

Ⅳ. Selection key:

Drilling pump: Priority is given to adapting to clear water media such as agricultural irrigation and industrial water supply, and the type is selected according to the drilling diameter (usually more than 4 inches) and head.;

API Type Rod Pump: For oil extraction, low-yield deep wells are selected with a fixed type at the bottom of the cylinder, sand-containing wells are adapted to the fixed type at the top, and intermittent pumping wells are recommended with a moving cylinder design. Tieling Dongsheng can provide more than 50 customized solutions.

As a qualified supplier of PetroChina and Sinopec, Tieling Dongsheng's API Type Rod Pump has been exported to the United States, Canada and other countries, and has shown excellent adaptability in deep wells and sand-containing wells above 2,500 meters.Choosing a compliant API Type Rod Pump is a key prerequisite for efficient oil extraction.

Reference materials:

[1] American Petroleum Institute. API 11AX Specification for sucker - rod pumps [S].

[2] International Organization for Standardization. ISO 9001 Quality management systems—Requirements [S].

[3] Drainage and Irrigation Machinery Branch of China Agricultural Machinery Industry Association.Selection guide for drilling pumps for agricultural irrigation [G].

[4] National Energy Administration.Specification for the selection of corrosion-resistant alloy materials for the oil and gas industry: SY/T 6556-2019 [S].

[5] Material Procurement Management Department of China National Petroleum Corporation.China Petroleum Materials Procurement Network [EB/OL].

[6] Materials and Equipment Department of China Petrochemical Corporation.Sinopec Materials Electronic Bidding and Bidding Trading Platform [EB/OL].