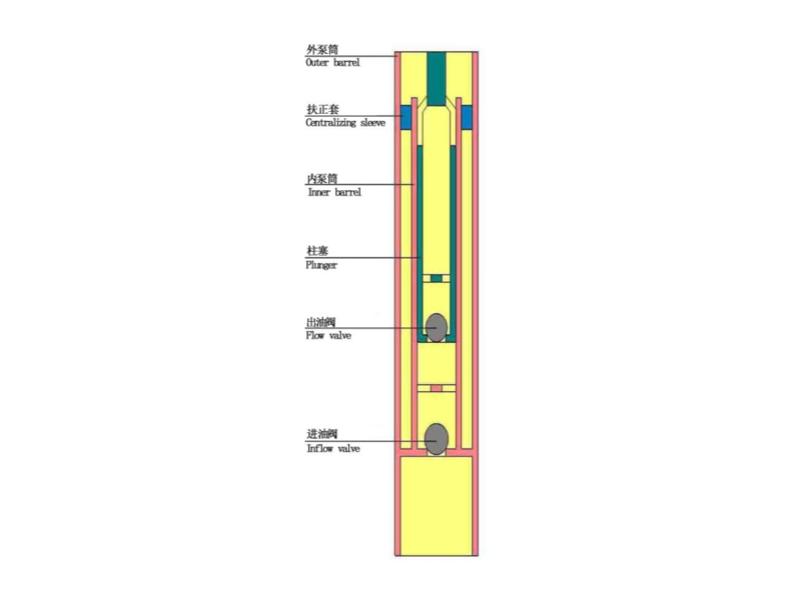

There are many factors that affect pump efficiency, but from the three basic links of the deep-well sucker rod pump (the piston gives up volume, crude oil enters the pump and is discharged from the pump), it can be summarized into the following three aspects.

(1) Elastic expansion and contraction of the sucker rod string and the tubing string. Due to the working characteristics of the deep-well sucker rod pump, the sucker rod string and the tubing string are subjected to alternating loads during operation, resulting in elastic expansion and contraction, making the piston stroke smaller than the bare rod stroke, thereby reducing the volume given up by the piston.

(2) The influence of gas and insufficiency. When the oil-gas mixture is sucked into the pump, the gas occupies part of the space given up by the piston, and the oil does not have time to enter the pump. Or when the pump displacement is greater than the oil supply capacity of the oil layer, the amount of oil entering the pump will also be reduced.

(3) The influence of leakage. The gap between the piston and the bushing and the leakage between the valve and other connecting parts will reduce the actual displacement. As long as the manufacturing quality and assembly quality of the pump are guaranteed, the impact of leakage will be small within a certain period of time after the pump is installed. However, when the liquid is corrosive or contains sand, the leakage will increase rapidly due to corrosion and wear on the pump. Wax deposition and sand deposition in the deep-well sucker rod pump will cause the valve to close loosely, or even get stuck and seriously damage the operation of the pump. In these cases, in addition to improving the structure of the deep-well sucker rod pump and improving the corrosion resistance of the pump, the main measures are to take sand and wax prevention measures, and regularly inspect the pump to maintain the normal operation of the pump.

Measures to improve pump efficiency:

To improve the efficiency of the deep-well sucker rod pump, it is necessary to try to reduce the above three effects.

1. The influence of the elastic expansion and contraction of the sucker rod and the tubing on the piston stroke The piston stroke is less than the rod stroke, which is an inevitable factor causing the pump efficiency to be less than 1. The greater the elastic expansion and contraction of the sucker rod column and the tubing column, the greater the difference between the piston stroke and the rod stroke, and the lower the pump efficiency. The different loads on the sucker rod column will result in different expansion and contraction deformations. As mentioned above, the loads on the sucker rod column mainly include: the weight of the sucker rod column and the weight of the liquid column above the piston (collectively referred to as static load), the inertial load of the sucker rod column and the liquid column, and the vibration load of the sucker rod column (collectively referred to as dynamic load). The following will study the elastic deformation of the sucker rod column and the oil pipe caused by these loads, as well as the impact on the piston stroke.

2. The impact of gas on pump efficiency:

During the exploitation period of deep-well sucker rod pump, most oil fields are produced at a flow pressure lower than the saturation pressure. Even if they are produced at a pressure higher than the saturation pressure, the pump port pressure is lower than the saturation pressure. Therefore, when pumping, both gas and liquid are always pumped into the pump at the same time. The gas entering the pump will inevitably reduce the amount of liquid entering the pump and reduce the pump efficiency. When the gas influence is serious, "gas lock" may occur, that is, during pumping, due to the compression and expansion of gas in the pump, the suction and discharge valves cannot be opened, and the phenomenon of no oil being pumped out occurs.

If the oil layer energy is low or the crude oil viscosity is high, the suction resistance of the deep-well sucker rod pump is very large. Often, the piston starts to move downward before the oil fills the pump barrel, resulting in the so-called underfilling phenomenon, which reduces the pump efficiency. In this case, the pump can generally be deepened to increase the sinking degree, or reasonable pumping parameters can be selected to adapt to the oil supply capacity of the oil layer. For heavy oil, viscosity reduction measures can also be taken.

3. Leakage effect:

The leakage that affects the pump efficiency includes:

(1) Discharge part leakage. The gap leakage between the piston and the bushing and the floating valve leakage will reduce the amount of oil discharged from the pump.

(2) Suction part leakage. The fixed valve leakage will reduce the amount of oil entering the pump.

(3) Other parts leakage. Although the pump is working normally, the pump efficiency will be reduced due to leakage due to the looseness of the oil pipe thread, the pump connection part and the oil drain.