Ⅰ.The use of rod pumps to pump oil is the core method of oilfield mechanical oil recovery:

In oilfield development, when the oil well cannot be self-injected due to insufficient formation energy, thick crude oil, etc., or the output is too low, it is necessary to use mechanical energy to recover oil. At present, the main mechanical oil recovery methods we use include gas lift oil recovery and deep well oil sucker rod pump oil recovery, and rod pump pumping is one of the important types of deep well oil sucker rod pump oil recovery. With the advantages of simple structure and easy maintenance, it is most widely used in oil fields around the world, especially in shallow and medium-sized oil wells.

1. Application scenario and technical status:

Applicable conditions: Our deep well oil sucker rod pump is suitable for oil wells where formation energy drops, raw energy is low, or petroleum is thick, and continuous oil recovery can be achieved through mechanical power.

Technology proportion: Although rodless pumps (such as hydraulic piston pumps and electric submersible oil pumps) are increasingly used in deep wells and complex working conditions, deep well oil sucker rod pump devices still account for the vast majority of mechanical oil production. Until now, our deep well oil sucker rod pump is still the key technology for stable production in oil fields.

2. System composition and collaborative work:

Under normal circumstances, our deep well oil sucker rod pump rod pump pumping system is composed of three parts: ground pumping unit, intermediate pumping rod column, and underground pumping pump.:

Oil pumping unit: Provides ground power, and converts the rotational movement into the reciprocating movement of the light rod through the crank connecting rod mechanism.

Pumping rod column: Connects the ground and the underground to transmit power to the plunger of the oil pump.

Oil pump: It directly completes the oil absorption and oil discharge, which is the core equipment of the underground.

Ⅱ. Structure and working principle of key devices:

1. The oil pumping unit is the core of ground power:

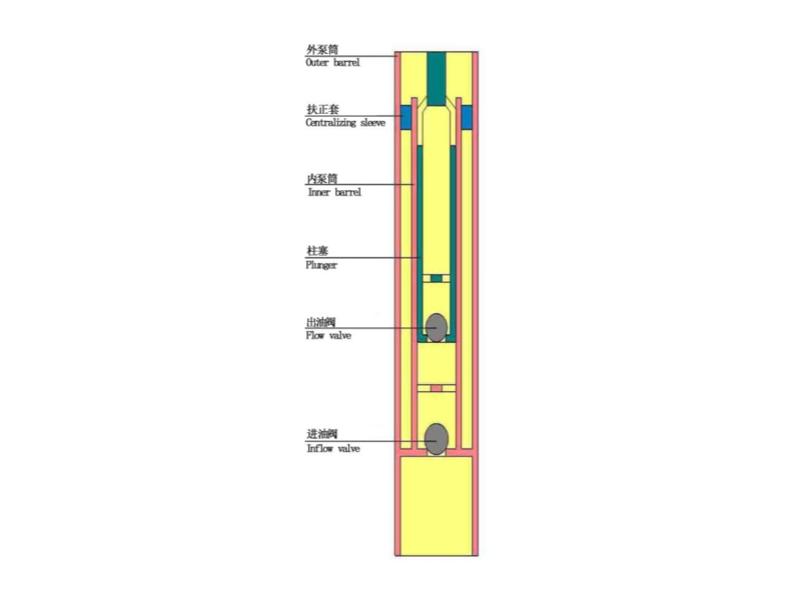

Deep well oil sucker rod pump is the most common type. Our company's deep well oil sucker rod pump can be divided into outer cylinder, centralizer, inner cylinder, flow valve and inflow valve according to the structure:

Outer cylinder: Mainly to withstand the static pressure of the liquid column, it forms a double-layer sealing structure with the inner pump cylinder.

Centralizer: Keep the pump body vertical and reduce the friction of the well wall.

Inner cylinder: The actual liquid pumping channel, which works with the plunger seal.

Flow valve: The liquid outlet valve is installed above the plunger and opens when the plunger strokes upward.

Inflow valve: Allows liquid to enter the pump cylinder to prevent reflux.

2. Our deep well oil sucker rod pump is the “executor” of underground oil production:

The oil pump directly determines the oil recovery efficiency and needs to adapt to the harsh environment of underground high temperature, high pressure, and sand-containing wax corrosion. It is mainly divided into tubular pumps and rod pumps:

Tubular pump:

Structure: The outer cylinder and bushing follow the tubing down into the well, the plunger enters through the sucker rod column, and the fixed valve needs to be salvaged or operated through the oil drain.

Features: Simple structure, low cost, and large displacement, but the inspection pump requires an oil pipe, which is suitable for shallow and high-yield wells.

Rod pump:

Structure: The whole body enters with the pumping rod column, and the circlip spring is fixed in the oil pipe. There is no need for the oil pipe to be used for the inspection of the pump.

Features: Suitable for deep and low-yield wells, but the structure is complex, the cost is high, and the displacement is small.

Core components: it consists of a working cylinder, a plunger, a swimming valve (discharge valve), and a fixed valve (suction valve), which realizes the suction and discharge of liquid through the reciprocating movement of the plunger:

Upper stroke: The plunger goes up, the swimming valve is closed, the fixed valve is opened, and the liquid is sucked into the pump.

Next stroke: The plunger goes down, the fixed valve is closed, the swimming valve is opened, and the liquid in the pump is discharged into the tubing.

Ⅲ. Iteration and future of rod pump technology:

With its maturity, economy and ease of maintenance, our deep well oil sucker rod pump system is still the “main force” of oilfield oil production. Our deep well oil sucker rod pump can further improve its efficiency by optimizing the combination of parameters, improving the sand-proof and wax-proof process, and accurately diagnosing working conditions. In the future, we will also upgrade the rod pump system to automation and precision with the penetration of intelligent technologies (such as downhole sensors and remote monitoring power diagrams), and at the same time apply it in concert with rodless pump technology to jointly meet the mining challenges of complex reservoirs.