Ⅰ. The structure of deep well oil sucker rod pump:

Pumping rod pump is also called deep well rod pump. Our deep well oil sucker rod pump is a special equipment for mechanical oil recovery with rod pump.Under the pump, it is at a certain depth below the moving liquid level in the well shaft, and relies on the sucker rod to transmit the power of the sucker to extract the crude oil from the ground.

It is divided into combined pumps and whole cylinder pumps according to whether there is a bushing or not. The working cylinder of the combined deep well oil sucker rod pump has several bushings, and it is pressed by the upper and lower compression joints; the working cylinder of the whole pump is a seamless steel pipe without a bushing inside. It is divided into two types: tubular pump and rod pump according to its installation method and structure in the well.

Ⅱ. Structure and characteristics of tubular pump:

The tubular pump is installed at the lower end of the tubing and is the continuation of the tubing.

1. Structure of tubular deep well oil sucker rod pump:

The tubular deep well oil sucker rod pump consists of four parts: a working cylinder, a piston, a swimming valve and a fixed valve.

(1) The working cylinder of deep well oil sucker rod pump: it consists of an outer tube, a bushing and an upper and lower compression coupling.The outer pipe is equipped with a bushing of multi-section concentric cylindrical pipes, the upper and lower ends are pressed by compression hoops, the upper hoop is connected to the tubing, and the lower hoop is connected to the fixed valve assembly.

(2) The piston of deep well oil sucker rod pump: a hollow cylinder made of seamless steel pipe, with threaded swimming valves at both ends. The outside of the piston is chrome-plated and has a ring-shaped sand-proof groove. The ring-shaped sand-proof tank has two functions: first, it can store a small amount of sand to prevent the sand from wearing the piston and the surface of the bushing. The second is that it can store a small amount of oil and play a lubricating role.

(3) The swimming valve of deep well oil sucker rod pump: it consists of a valve ball, a valve seat, and an open valve cover. One swimming valve of the two-valve tubular pump is installed at the upper end of the piston, and the two swimming valves of the three-valve tubular pump are installed at the upper and lower ends of the piston.

(4) The fixed valve of deep well oil sucker rod pump: it consists of a valve seat, a valve ball and an open valve cover.

2. Characteristics of tubular pumps:

(1) The pump diameter is large and the displacement is large, which is suitable for shallow wells with high output and high sand content.

(2) Suitable for wells with small gas production.

(3) The structure is simple, the processing is convenient, and the price is cheap.

(4) Since the working cylinder is connected to the lower end of the oil pipe, the oil pipe needs to be started when the workover is inspecting the pump, and the workover workload is large.

Ⅲ. Structure and characteristics of rod pump:

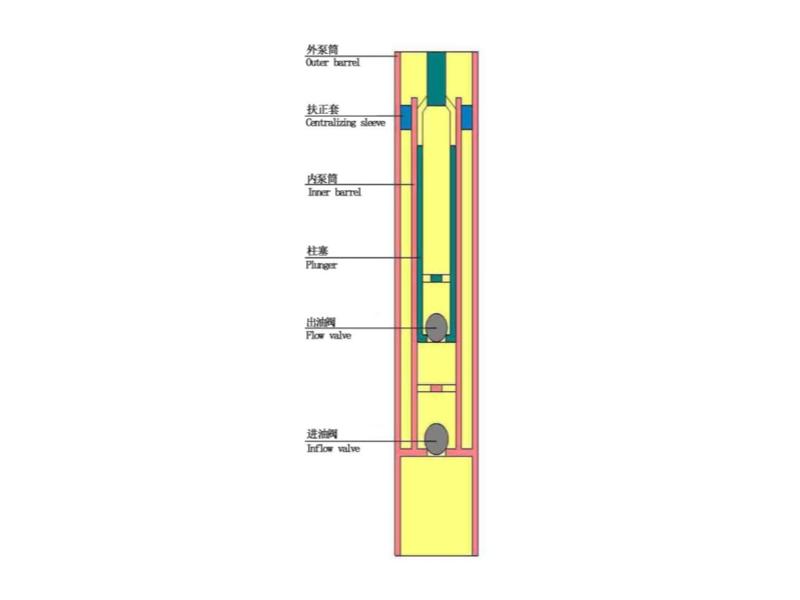

The rod pump of deep well oil sucker rod pump has two inner and outer working cylinders. The outer working cylinder is connected to the lower end of the oil pipe, and the inner working cylinder is connected to the piston at the lower end of the oil rod. The whole goes down to the outer working cylinder, which is fixed by the tapered lock pre-installed in the outer working cylinder.

1. Structure of rod pump:

(1) Piston with swimming valve.

(2) Inner working cylinder with fixed valve.

(3) Tapered lock.

(4) Hanging to the outer working cylinder at the lower end of the tubing.

2. Characteristics of rod pump:

(1) It is convenient to check the pump, and the oil pumping rod can be pulled out.

(2) The pump diameter is small, which is suitable for deep wells with low output.

(3) The pump can be tested before going down the well, thus ensuring the quality.

(4) The structure of the rod-type deep well oil sucker rod pump is more complex, difficult to process, and costly.

(5) It cannot be used in shallow wells that are easy to produce sand, and the inner and outer working cylinders are easy to get the pump stuck in the tubing due to sand stuck.

Ⅳ.The working principle of the sucker rod pump:

Upper stroke: The piston goes up, the swimming valve is closed, and the pressure in the pump cylinder drops. When the pressure in the pump cylinder is lower than the pressure at the inlet of the pump, the fixed valve opens and the liquid enters the pump. At the same time, the wellhead discharges the piston to let out the volume of liquid in the pump cylinder.

Down stroke: The piston goes down, the pressure in the pump cylinder rises, the swimming valve is opened, the fixed valve is closed, the liquid is discharged from the pump into the tubing above the piston, and the volume of liquid entering the light rod is discharged from the wellhead at the same time.

The above is our introduction to the structure and principle of deep well oil sucker rod pump. Do you have a better understanding of it? We are a leading manufacturer of oil well pumps, sucker rod pumps and downhole tools for deep well drilling in China.Our deep well oil sucker rod pump adopts the classic double-layer pump barrel structure design, which has strong sealing and high pumping efficiency. Compared with the traditional single-layer pump barrel design, our sucker rod pump structure is more adaptable to the high-pressure environment of deep wells, and the sealing performance is stable and does not decrease. If you are interested in our products, we always welcome you to visit our workshop and factory!