1. Working principle of gas locking prevention oil well pump:

Gas locking prevention oil well pump is a mechanical oil production equipment, which is used for non-flowing oil well suction production, especially suitable for low permeability, light oil reservoirs, high oil-gas ratio crude oil, medium-deep inclined and pumped oil production. Generally speaking, low permeability oil fields have different degrees of "five sensitivities" (water sensitivity, acid sensitivity, salt sensitivity, alkali sensitivity, and speed sensitivity). In order to increase the production of oil wells and eliminate the damage caused by "five sensitivities" to the formation, oil formation protection measures are generally taken. One measure is to do not kill the well, which is generally used when the downhole pipe string structure is simple and the downhole tool shrinks and expands relatively small. It mainly uses downhole and ground tools and equipment to separate the environment below the wellhead and the external environment of the wellhead during the operation. However, the current domestic technology for not killing the well is not mature (it is difficult to achieve when the pressure is higher than 5MPa), and it is even more difficult to achieve when the downhole pipe string is complex, the shrinkage and expansion are relatively large. Another measure is well-killing operation, which is mainly aimed at wells with relatively high pressure and complex downhole pipes. Generally, oil layer protective agents are added to the fluid entering the well to reduce the pollution of the formation by the fluid entering the well, but the fluid entering the well will inevitably cause damage to the formation. Therefore, for various different situations, Gas locking prevention oil well pump is necessary to adopt non-killing operation methods with different scopes of use.

2. Methods:

There are currently two main types of downhole deep well pumps used for oil extraction. One is a tubular pump, which is characterized by the fact that when going down the well, the pump cylinder and the plunger are generally separated. The pump cylinder is first lowered into the well with the oil pipe. When it reaches the predetermined position (pump hanging depth), the pump plunger is connected to the bottom of the sucker rod and lowered into the well. After hitting the pump, the column is lifted to adjust the anti-impact distance. Therefore, when inspecting the pump, all the oil pipes on the pump must be lifted out before the pump barrel can be taken out, and the workload is relatively large. The other is a rod pump, whose pump inspection procedure is quite different from that of a tube pump. The pump can be lowered into the oil pipe as a whole. When lowering the oil pipe string, the fixed support joint assembly must be connected to the oil pipe at a predetermined pump hanging depth. When lowering the pump, the top connecting joint of the rod pump is connected to the bottom end of the sucker rod string. The entire pump is suspended at the lower end of the sucker rod and lowered into the well with the sucker rod until the locking device on the pump is stuck in the fixed locking support joint assembly on the oil pipe. Then the plunger is lifted to adjust the anti-shock distance. When inspecting the pump, only the sucker rod needs to be pulled out to pull out the pump barrel. Therefore, the workload of pump inspection is small and it is more suitable for use in medium-deep wells, deep wells and low-porosity and low-permeability oil reservoirs with poor formation fluid supply capacity. From the current field application of these two pumps, although the tubular pump has various performance pump types that can meet the mining under different circumstances, it is difficult to achieve the non-suppression pump inspection operation without relying on special ground equipment: the existing rod pump can achieve the non-suppression pump inspection operation using ordinary operating equipment, but it cannot meet the needs of low permeability oil reservoirs, high oil-gas ratio crude oil, and inclined well mining.

The purpose of the utility model is to overcome the shortcomings of the above technology and provide a new rod pump that can prevent gas and blowout and is suitable for inclined well pumping-Gas locking prevention oil well pump.

To achieve the above purpose, Gas locking prevention oil well pump adopts the following measures:

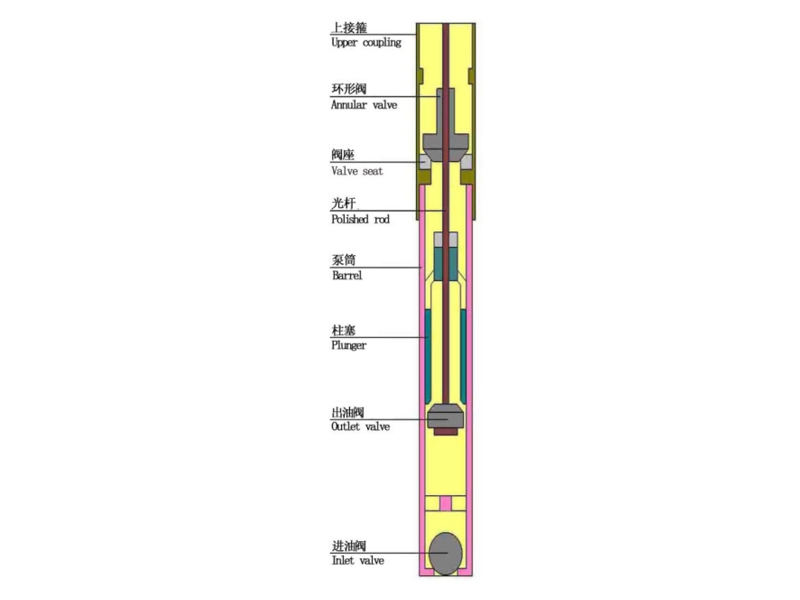

The gas locking prevention oil well pump is mainly composed of an outer tube, a pull rod, a pump, a piston, etc. Its outer structure is: the upper part of the outer tube is connected to the support seat through a coupling, and the support seat is connected to the oil pipe variable buckle joint through an outer support joint: the lower end of the outer tube is connected to the one-way valve body through the one-way valve upper joint, and the lower end of the one-way valve body is connected to the lower joint. The upper structure of the inner layer of the gas locking prevention oil well pump is as follows: the upper end of the tie rod is connected to the sucker rod joint through two parallel caps, and the lower end is connected to the upstream movable valve cover with a parallel cap. The middle structure of the inner layer of the pump is as follows: the upper end of the pump cylinder is connected to the leather cup seat through the upper joint of the pump barrel, the leather cup seat and the support pipe are connected together through the spring claw, and the upper end of the support pipe is connected to the annular valve cover through the inner support ring compression joint; the lower end of the pump barrel is connected to the fixed valve cover, and the fixed valve cover is connected to the through rod through the fixed valve joint. The upper end of the piston is connected to the upstream movable valve cover through the upper joint of the piston, and the lower end is connected to the piston bottom joint through the downstream movable valve cover.

An upstream movable valve composed of an upstream movable valve ball and an upstream movable valve seat is provided in the upstream movable valve cover above the piston, and a downstream movable valve composed of a downstream movable valve ball and a downstream movable valve seat is provided in the downstream movable valve cover below the piston: the purpose of setting the upper and lower movable valves is to play a safety role. When one movable valve is not closed tightly for some reason, the other movable valve plays a sealing role. A fixed valve consisting of a fixed valve ball and a fixed valve seat is provided in the fixed valve cover at the lower end of the pump barrel. The upper movable valve cover, the lower movable valve cover and the fixed valve cover are composed of multiple cylinders, among which several small cylinders cut the large cylindrical surface in the middle into several arc surfaces, and the large cylinder in the middle cuts the small cylindrical surface into only one arc surface. With this structure, the valve ball can only move up and down in the large cylinder in the middle, and is straightened by the cut small arc surface. The liquid passes through the gap between the four small cylindrical surfaces and the valve ball. Since the valve ball can only move up and down and cannot deviate to the side, it can quickly return to the valve seat by relying on its gravity, thereby reducing the time that the valve ball lags behind the movement of the pumping rod when opening and closing, which is conducive to working in inclined wells.

At the upper part of the gas locking prevention oil well pump, an anti-gas annular valve consisting of annular valve joint, annular valve upper seat, sealing ring and annular valve lower seat is provided in the annular valve cover. The ring valve joint fixes the sealing ring in the ring valve upper seat through threads, and the ring valve lower seat is fixed in the ring valve cover through the upper end of the inner support ring compression joint; the upper end of the pull rod passes through the ring valve joint, the ring valve upper seat, and the sealing ring and is connected to the sucker rod joint. The purpose of setting the anti-gas ring valve is to reduce the opening pressure of the floating valve, reduce the volume of the residual gas in the pump suction chamber, increase the volume of the pump chamber suction fluid, thereby reducing the effect of gas on the pump suction liquid and eliminating the occurrence of gas lock; at the same time, the ring valve isolates the pump from the upper oil pipe, so that sand is not easy to deposit in the pump barrel and piston to cause sand jam: on the other hand, since the well fluid discharged by the ring valve can flush the sand deposition position, it can be used for oil wells with a certain amount of sand.

In the lower part of the gas locking prevention oil well pump, the one-way valve body below the fixed valve is provided with an anti-blowout one-way valve composed of a through rod, a one-way valve seat, a one-way valve, a spring, and a spring seat. The one-way valve seat is fixed in the one-way valve body through the one-way valve upper joint, and the one-way valve is placed on the spring, and the spring is placed on the spring seat at the upper end of the lower joint. The one-way valve is a geometric body with a closed top end being a truncated cone or a cone, a large diameter cylinder in the middle, and a small diameter cylinder at the lower end. A long groove is opened on the large diameter cylinder from the end face of the top of the truncated cone or cone to communicate with the inside, and a boss is provided on the outer surface of the large cylinder to center the one-way valve in the one-way valve body. The purpose of designing a blowout prevention one-way valve is to realize the pump inspection operation without well pressure, and reduce the pollution of the formation caused by the fluid entering during the well pressure operation. The utility model adopts the above structure and has the following advantages: the pump inspection operation without well pressure can be realized without the help of special ground equipment, which reduces the operation cost; the sealing is reliable, which can effectively eliminate the gas lock phenomenon in the oil pumping process, increase the anti-gas function of the pump, improve the pump efficiency, and can adapt to the exploitation of sand-containing oil wells and inclined wells.

Friends who are looking to solve problems such as low permeability reservoirs, high gas-oil ratio crude oil, and inclined well mining are welcome to consult our gas locking prevention oil well pump. Our products have achieved good results in practical applications. If you want to know the specific data, please feel free to leave us a message! Looking forward to your inquiry!