Our thermal recovery sucker rod pump is specially designed for the field of thermal recovery in oil fields and is designed to solve the problem of steam recovery in heavy oil extraction. Our thermal recovery sucker rod pump is produced in Tieling Dongsheng Petroleum Machinery Co., Ltd. , our annual supply capacity reaches 20,000 pieces, and we promise a standard delivery cycle of 8-10 weeks to meet the needs of global oilfield projects.

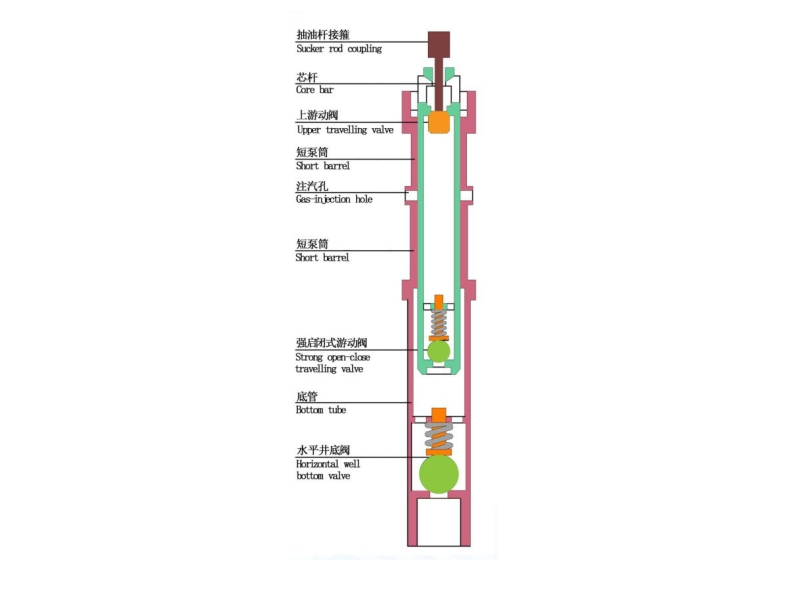

The core working principle of our thermal recovery sucker rod pump is a heat recovery mechanism based on steam injection. When the sucker rod is raised by 200mm, we will use a mechanical linkage device to make the plunger be raised synchronously, so that the steam injection hole of the sealed pipe is connected to the oil pipe to achieve efficient steam injection operation. When the plunger falls back, the cone surface (tolerance ±0.01mm) forms a metal seal with the pump cylinder, and the sealing pressure is as high as 15 Mpa. In terms of materials for the design and production of this thermal recovery sucker rod pump, we used Inconel 625 high temperature resistant alloy bushing for the steam injection channel, which can withstand continuous steam scouring at 350°C. In the field test of Liaohe Oilfield, the steam dryness retention rate was ≥85%. Our thermal recovery sucker rod pump has obvious advantages over other sucker rod pumps: The special design of oblique/horizontal wells (spiral guide groove in the plunger pump cylinder) allows our thermal recovery sucker rod pump to operate continuously in 83° high-angle wells for more than 180 days; The steam injection function is plasma sprayed with AlOo--tio₂ composite coating (hardness HRC65), so that the service life under the condition of 2% sand content is 2.5 times that of traditional pumps; We use a modular structure to directly connect API standard TBG tubing, without special tools, we can shorten the average pumping time to 4 hours, saving 67% of the time and cost than traditional heat recovery pumps.

In terms of technical parameters, our thermal recovery sucker rod pump can provide you with a variety of specifications to choose from: pump hole 44mm (plunger length 4.2~7.8m, pump constant 2.23), 57mm (pump constant 3.69), 70mm (pump constant 5.52), connecting tube size covers 2 7/8TBG to 3 1/2TBG, stroke range 3.0-6m, maximum outer diameter 88.5-108mm. The displacement calculation is based on the formula Q = K × S × N (Q is the daily displacement m3/d, K is the pump constant, S is the stroke m, and N is the stroke/min), which enables our thermal recovery sucker rod pump to be accurately adapted to different operating conditions. At the same time, we can also support the customization of the thermal recovery sucker rod pump suitable for you according to your other needs.

Our sucker rod pump is generally widely used in heavy oil steam wells, shale oil thermal recovery wells, old wells to increase thermal production and sideline heavy oil reservoirs. Its core value lies in realizing the integrated operation of the whole cycle of “steam injection-well stop-production”, without the need to replace the pipe column, and accurately controlling the amount of steam injection to avoid water intrusion and improve the recovery rate.

We Tieling Dongsheng Petroleum Machinery Co., Ltd. relying on a team of 20 engineering and technical personnel, focusing on structural optimization and material innovation, our sucker rod pump has passed ISO 9001, API 11AX certification and Sinopec and Sinopec supplier qualification audits. Our packaging adopts the dual protection of anti-rust oil +vacuum film, and the key components will be individually fixed to support EXW/FOB/CIF global logistics, and we will conduct pressure and performance tests within 72 hours before leaving the factory to make the product delivered safely.