The air lock problem in heavy oil mining is being gradually solved by our company. We Tieling Dongsheng Petroleum Machinery Co., Ltd. with the design of this mechanical valve, the forced valve rod pump has achieved a breakthrough in reducing the air lock rate by 90% in oil fields such as Liaohe and Daqing. Today we will pass some key questions and answers to uncover the innovative core of this domestic technology.

Q1: How does forced valve rod pump cure the chronic disease of “air lock” of traditional oil pumps?

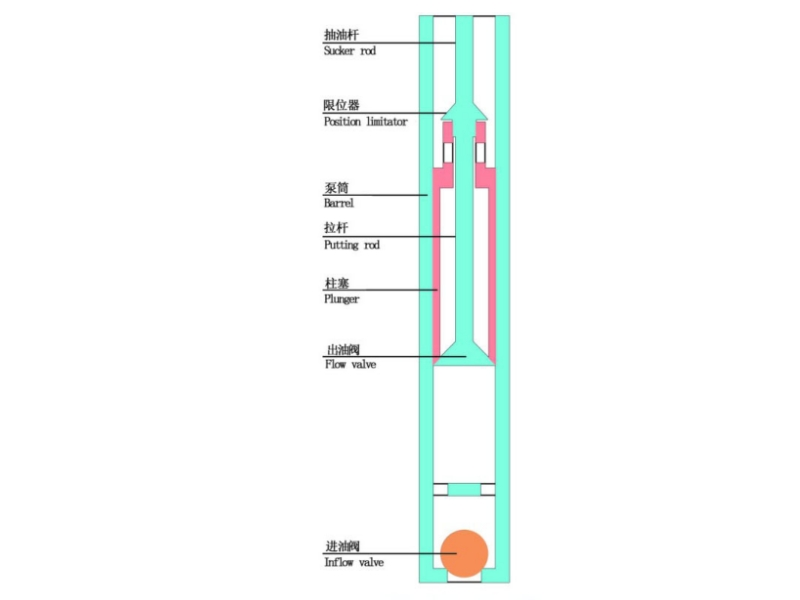

A: The core of our forced valve rod pump lies in the closed-loop control of the mechanical forced valve.Through a rigid connecting rod and a spring buffer mechanism (opening and closing time <0.1 seconds), the valve forcibly seals the crude oil during the upper stroke, and the pump chamber is opened instantly during the lower stroke, completely blocking gas retention. Actual measurements show that the design increases the response speed of the walking valve by 80%, and the air lock rate drops by 90%, injecting a “tonic” into the heavy oil well.

Q2: Facing ultra-heavy oils with a viscosity of >10,000 MPa·s, how can forced valve rod pump increase production capacity?

A: The modular structure gives it strong adaptability. The segmented plunger (adjustable from 0.6 to 1.2 meters) is matched with a 7.5-meter extendable pump barrel, which can match the ultra-deep well conditions of 2000-5000 meters.When using an 83mm pump diameter, the theoretical displacement is as high as 800m3/d, which is 35%-50% higher than the average daily production of conventional pumps, and the tungsten carbide coating is resistant to steam erosion at 400℃, and its life span is doubled.

Q3: In high-pressure sand-bearing wells, how does the forced valve rod pump balance durability and maintenance efficiency?

A: Triple hard-core guarantee:

1. Plunger laser hardening treatment (wear-resistant over 100,000 times) + precision filter structure, can withstand pressure of 5% sand content;

2. The plug-in design at the top of the valve group reduces the maintenance time from 8 hours to 2 hours;

3. The general rate of spare parts is >90%, and the cost of a single maintenance is 50,000 yuan.

Q4: Does the acidic environment (HSS≤2000ppm) restrict the application of forced valve rod pump?

A: Fully adapted!The duplex stainless steel valve body and PTFE seals have passed the NACE MR0175 certification, and the corrosion resistance covers the world's mainstream acidic oil fields.

Q5:Tieling Dongsheng Petroleum Machinery Co., Ltd. what are the results of the global practice of forced valve rod pump?

A: Our forced valve rod pump has covered domestic oil fields such as Liaohe and Daqing, and has been exported to the United States, Canada and other markets.With an annual production capacity of 20,000 units and a delivery cycle of 8-10 weeks, it provides a stable supply chain guarantee for heavy oil mining.

We Tieling Dongsheng Petroleum Machinery Co., Ltd. forced valve rod pump takes the innovation of mechanical valves as the fulcrum, and leverages the transition in the efficiency of heavy oil extraction. With our modular design, ability to withstand extreme operating conditions and rapid maintenance characteristics, we are redefining the technical benchmark of oil pumps.