Faced with multiple well conditions such as shale oil, high corrosion, and high sand content, rod pumps are still the equipment in artificial lift. Which types of pumps perform better? Which ones are suitable for different user needs? What are the advantages and limitations of plunger lift solutions?

What are the advantages of plunger lift solutions?

1. It is the most cost-effective lifting method for liquid-producing gas wells. Compared with gas lift or downhole pumps, the equipment and installation costs are relatively small, and the operation and maintenance costs are low.

2. Plunger lift solutions are very reliable. The main wear part is the plunger. It is easy to check for wear and damage and replace without interrupting production. The main causes of damage are too fast rise speed during operation or little or no fluid during operation, both of which can be avoided with proper control settings.

3. Minimum external power required. The main source of energy to drive the plunger is reservoir pressure. The control panel, control valves, and control system equipment require a small amount of power. Solar panels and batteries are sufficient to power this system. Plunger lift solutions tolerate paraffin, which often forms in the tubing. The plunger acts as a scraper to prevent it from accumulating and causing blockages.

Limitations of using plunger lift solutions:

Plunger lift solutions are a dynamic and complex process involving compressible gas expansion, gas and fluid acceleration, and different multiphase flow patterns present in the tubing above and below the plunger. Liquid production is usually limited to less than 20 b/d, but higher production is possible depending on reservoir pressure and inflow. Plunger lift is not applicable if the reservoir pressure is not sufficient to lift the plunger and liquid slug upward. Plunger lift cannot be run in horizontal sections. The maximum inclination is about 60°, which is the limit for bottomhole tools run by wireline. Plungers are usually used in vertical wells. They can tolerate some wellbore inclination, but their efficiency decreases as the inclination increases. Plunger lift solutions are not suitable when continuous production is required, such as in horizontal wells where intermittent flow causes liquid to fall back into the horizontal section.

Plungers can be used to remove wax and hydrates from the wellbore. After about a month of production through the tubing, the shale oil well cannot produce because of the wax on the upper part of the tubing blocking the tubing. It is necessary to use the continuous tubing hot wash to clean the wax in the tubing. If plunger lift solutions are used regularly, the wax in the tubing can be cleaned in time. Compared with the continuous tubing hot wash process, it is not only low-cost but also simple in process. After a period of production, shale oil and gas wells need to use wire tools to clear the wax and hydrates in the tubing. The plunger process can also be used to remove the wax and hydrates in the wellbore. Compared with the wire operation, this process is simple, has a short production impact, and is easy to operate on site.

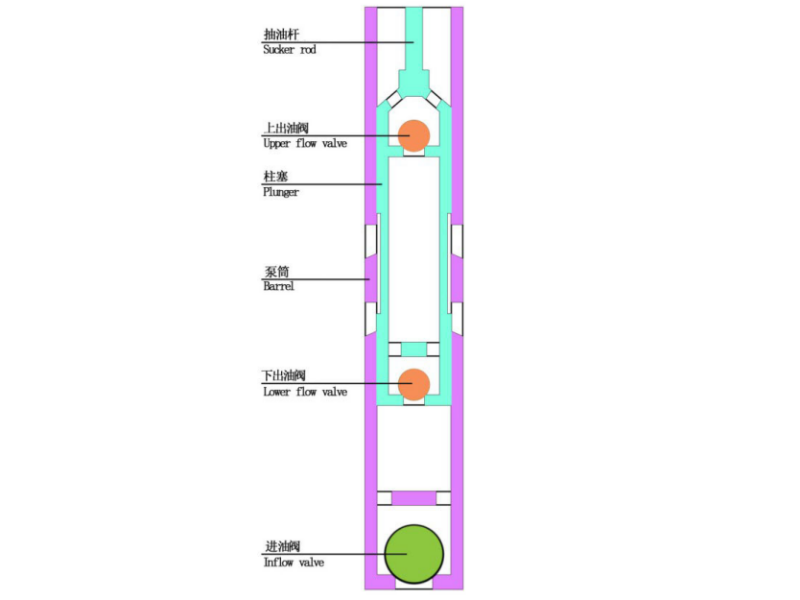

Recommended three types of rod pumps (technology-oriented)

| Pump type | Core advantages | Applicable oil wells |

| Anti-sand pump | Abrasion resistance, blocking resistance, and anti-locking | Shale oil containing sand, low-pressure heavy oil wells |

| Anti-corrosion pump | Alloy material is resistant to CO₂/H₂S corrosion | Acidizing wells, hydrogen sulfide blocks |

| Thermal recovery pump | High temperature resistance and anti-coking | Steam stimulation/steam injection thermal recovery wells |

In the process of cooperation with global leading companies such as China Shipbuilding Group, SLB, Weatherford, Sinopec and China National Petroleum Corporation, we continue to accumulate project experience and improve technical strength and service level. You don’t need to worry about experience. Dongsheng has provided plunger lift solutions to more partners. Friends who need artificial lifting solutions can leave us a message, and our technical department will provide you with professional customized solution suggestions!