11-07/2025

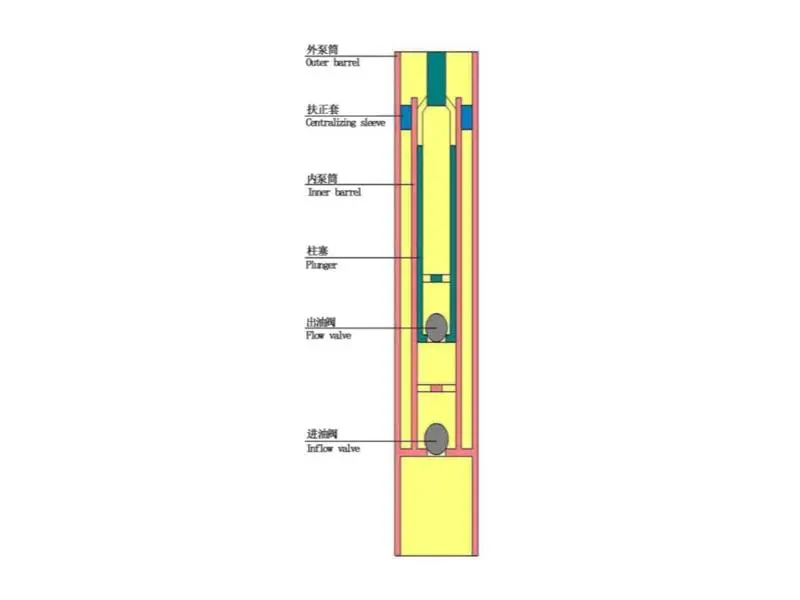

Complex underground working conditions, high temperature, high pressure, medium corrosion and high-frequency friction between components often cause damage to the internal structure of the sucker rod pump and affect the service life of the equipment. As an important core component of the sucker rod pump, cages for downhole pump relies on its own performance to provide a reliable solution to this problem and has become the key support to ensure the efficient operation of the sucker rod pump.