In the underground world of oil extraction, API standard sucker rod pump is like a tireless "underground miner", lifting crude oil from deep strata to the surface day and night. How does this seemingly mysterious equipment work? What "special skills" does it have to cope with different extraction environments? Today, we will unveil the technical veil of API standard sucker rod pump.

1. The core working principle of API standard sucker rod pump:

1. The secret of oil extraction in reciprocating motion:

The working principle of API standard sucker rod pump is essentially a special form of "reciprocating pump", and its core components include pump barrel, plunger, oil inlet valve and oil outlet valve. When the sucker rod column drives the plunger to reciprocate in the pump barrel, a subtle energy conversion begins.

In the upstroke (suction stage), the plunger moves upward, the volume of the pump chamber increases to form a negative pressure, the oil outlet valve is closed, the oil inlet valve is opened, and the crude oil is "sucked" into the pump chamber under the action of the sinking pressure. This process is like sucking a drink with a straw, and negative pressure is the key driving force.

During the downstroke (discharging stage), the plunger moves downward, the pressure in the pump chamber increases, the inlet valve closes, the outlet valve opens, and the crude oil is "squeezed out" of the pump chamber and lifted to the ground along the tubing. The whole process is similar to an air pump, and fluid transportation is achieved through volume changes.

2. Key factors affecting the efficiency of API standard sucker rod pump:

Under ideal conditions, the volume of liquid discharged by the plunger of the API standard sucker rod pump each time it reciprocates is equal to the volume given up by the plunger, but in actual production, the pump efficiency (actual output / theoretical output) is restricted by multiple factors:

The alternating action of the elastic expansion and contraction of the rod and tubing liquid column load makes the sucker rod and tubing expand and contract like a spring, resulting in a plunger stroke that is smaller than a bare rod stroke. For example, this "elasticity loss" in deep wells may reduce the pump efficiency by 10%-20%.

Influence of gas and filling When the gas content of the well fluid is high, the compression and expansion of the gas in the pump will cause "gas lock", making the valve unable to open and close normally. When the oil layer is not supplied with enough fluid, the pump chamber will not be able to "drink enough" and the efficiency will be reduced.

Leakage problem The gap between the plunger and the pump barrel, the poor sealing of the valve, etc. will cause well fluid leakage. The leakage of a new pump is about 5%-10%, while the leakage rate of a severely worn pump may exceed 30%.

3. Practical strategies to improve pump efficiency:

In response to the above challenges, oilfield engineers have summarized a set of efficiency-enhancing combinations:

Optimize working parameters. Heavy oil wells use the "large stroke, small stroke" mode to reduce the impact of gas; for wells with continuous spraying and pumping, "large stroke and fast pumping" is used to enhance the induced spraying.

Improve equipment structure. Use tubing anchors to fix the tubing to reduce elastic expansion and contraction losses; use anti-gas anchors to separate gas and increase the filling degree of the pump chamber.

Material upgrade. The plunger surface is chrome-plated or spray-welded, and the pump barrel is made of wear-resistant alloy to extend the equipment life and reduce leakage.

2. Family pedigree of API standard sucker rod pump: Type and structure:

1. Tube pump VS rod pump:

The tube pump has a simple structure, low cost, large pump diameter and high displacement, just like a "strongman" suitable for high-yield shallow wells. However, the oil pipe needs to be pulled out when inspecting the pump, and the workload is large.

The rod pump is lowered into the well as a whole with the sucker rod. There is no need to pull the oil pipe when inspecting the pump. It is suitable for deep wells and oil wells that need frequent well repairs, and can be called a "flexible engineer". However, the pump diameter is limited by the oil pipe, and the displacement is relatively small.

2. Soft-sealed plunger pump: "sealing expert" for special environments

Unlike metal plunger pumps, soft-sealed plunger pumps are made of oil-resistant rubber or nylon and other materials to make leather cups, sealing rings and other components, and rely on pressure difference to expand the seal to form an effective seal. This type of pump is suitable for oil wells with less sand and temperatures below 82°C, and is widely used in shallow wells and medium-deep wells.

3. Combined API standard sucker rod pump:

The pump barrel is composed of dozens of short sleeves set in the outer tube. It has the advantages of high pump efficiency, long stroke, light weight, and convenient loading and unloading. It is especially suitable for long-distance transportation and complex well conditions. It is an important direction for the development of API standard sucker rod pump in the future.

3. Downhole auxiliary equipment:

1. Tubing anchor:

Unanchored tubing will cause fatigue damage, bending deformation and other problems due to the alternating action of liquid column load. Tubing anchor fixes tubing by mechanical or hydraulic means, reduces elastic deformation and thread wear, and improves pump efficiency by 10%-15%.

2. Air anchor and sand anchor:

The air anchor uses the difference in oil and gas density to separate gas through slippage, centrifugal effects, etc., reduce gas entering the pump, and the gas separation efficiency can reach 60%-80%.

The sand anchor uses the difference in liquid and sand density to separate sand particles in the rotating flow and sink into the tail pipe to protect the pump from sand wear.

3. Oil drainer: The oil drainer installed above the pump opens the oil drain hole during well repair to drain the liquid in the oil pipe into the well, avoiding the overflow of well fluid when lifting the pipe, and ensuring the safety of the operation.

The oil field development has entered the middle and late stages, and the reservoir conditions have become complicated. The API standard sucker rod pump is developing towards intelligence, efficiency and multi-function:

1. Intelligent monitoring implants sensors to monitor the pump condition in real time, and realize remote diagnosis and optimization through the Internet of Things technology.

2. The material adopts new materials such as nano-coating and super wear-resistant alloy to further improve the life of the equipment.

3. The integrated design integrates the API standard sucker rod pump with air anchors, sand anchors, etc. to achieve "mining-division-discharge" integration and improve mining efficiency.

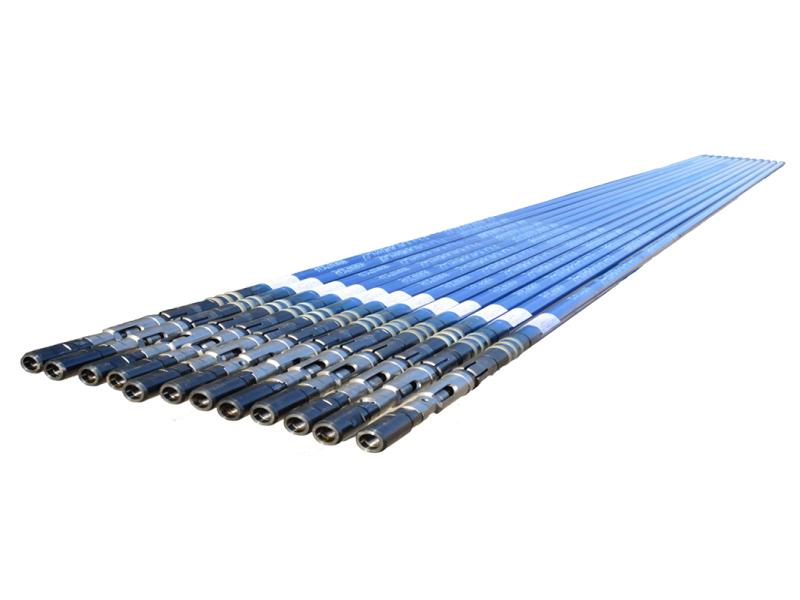

In addition to the tube pump and rod pump accessories mentioned above, we at Dongsheng also have special API standard sucker rod pump including: Displacement Varying Sucker Rod Pump, Movable Barrel Sand Control Oil Well Pump, Separate Layer Production Pump, Anti Gas Sucker Rod Pump, etc., nearly 20 types of API standard sucker rod pump. We hope that you can find the API standard sucker rod pump you need in Dongsheng. At the same time, we also welcome major buyers to our factory for inspection. We will conduct offline face-to-face exchanges and look forward to your arrival.