We all know that although the artificial lift sucker rod pump is only a part of the downhole equipment, its selection has a particularly large impact on the life and production capacity of the well. Especially after the shale oil wells in the United States enter the middle and late stages, the well conditions are becoming more and more complicated, and the production is gradually declining. The quality and performance of the artificial lift sucker rod pump are directly related to whether the production can be stabilized and the shutdown and maintenance can be reduced.

In recent years, we have cooperated with customers and observed the performance of various artificial lift sucker rod pumps and listened to a lot of feedback from front-line operations. Combined with these real situations, we have sorted out some rod selection suggestions for the shale oil area in the United States, hoping to help everyone's actual operation.

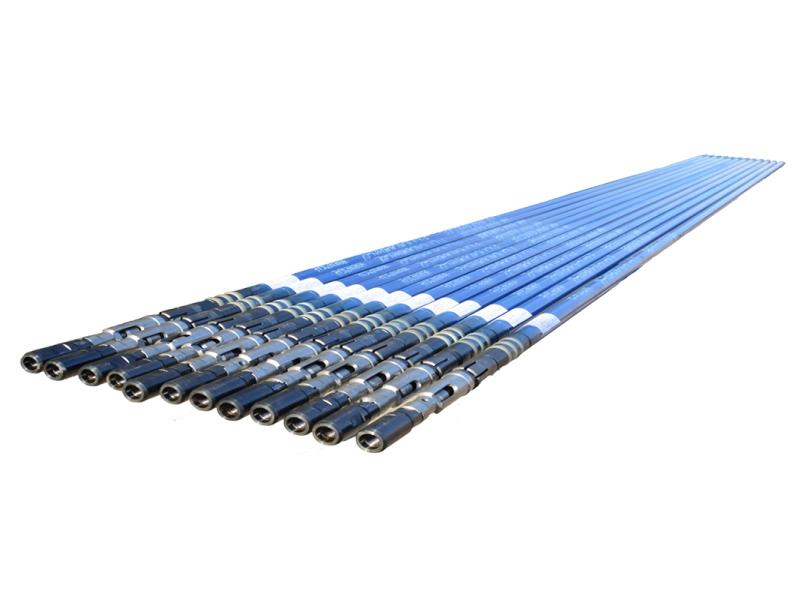

In the process of our cooperation with many operating companies in the United States, the following three rod types are being frequently used:

1. D-grade or higher strength steel sucker rod pump.

2. Wear-resistant sucker rod pump with coating (such as tungsten coating, hard alloy plating).

3. Hollow sucker rod pump or flexible composite lightweight sucker rod pump.

These are not just talk on paper, but configuration consensus that has been verified and gradually formed in the core shale producing areas.

Why choose them? Combined with the on-site situation, there are two characteristics of American shale wells:

1. Deep well, high impact, and high tension; 2. Long horizontal section and heavy friction loss.

High-strength steel sucker rod pump (such as D grade, KD grade): suitable for the working conditions of high impact and high load in the initial stage of mining, supporting the whole set of rod strings to operate safely at a well depth of more than 3,000 meters.

Coated sucker rod pump: Coating (such as tungsten plating) can effectively reduce the friction between the rod and the tubing, especially in the long horizontal section. At the same time, it also has good corrosion resistance and adapts to complex well conditions such as H₂S.

Hollow sucker rod pump/composite sucker rod pump: used in the back section and horizontal section of the well, effectively reducing weight, improving pump efficiency, and reducing the risk of broken rods. We have actually tracked several wells. After using this type of rod string, the pump inspection cycle can be extended by at least 25%.

What benefits do these rod pumps bring?

We have seen such a change on site more than once:

The rod string is more stable; the pump inspection cycle is longer; the failure rate is reduced. Specifically: the combination of high strength + coating + light weight reduces the overall risk of wear and fatigue fracture. Compared with ESP or gas lift systems, rod pumps have a simple structure and low maintenance threshold, which is especially suitable for economic development in the period of low production decline. The hollow sucker rod pump + low friction design makes the entire pumping efficiency higher. Especially when the liquid column pressure head is low, the advantage is obvious.

Practical advice: How to properly match the rod?

Based on the well depth, structure and gas-liquid ratio, we give the following selection suggestions:

| Working conditions | Recommended configuration |

| >3000m deep well, high tension | Use D-grade or KD/HA high-strength rods |

Long horizontal section, high friction | Use coated rods (tungsten or alloy) |

| Presence of corrosive media | Add anti-corrosion coating or use materials above K-grade |

Production enters a declining period | Use hollow rod + short-stroke pump system combination |

One of our customers used a D-grade high-strength steel sucker rod pump + middle section tungsten coating + horizontal section hollow rod configuration in a well with a depth of 3990 meters in Texas.

The system has been running continuously for more than 12 months without major failures and has saved about 12% of operation and maintenance expenses. This is not an isolated case, but a similar trend we have observed in many shale areas.

Final suggestion: This combination is the "golden configuration" for current shale wells

If you are operating a US shale oil well, especially an oil well that has entered the production decline period, we recommend:

Use D-grade or KD high-strength steel sucker rod pump for the upper section, tungsten-coated or alloy-plated wear-resistant sucker rod pump for the middle section, and hollow or composite lightweight sucker rod pump for the horizontal section.

This combination can effectively reduce wear, avoid rod breakage, extend service life, and reduce operation and maintenance costs. It is one of the most reliable and economical options currently available.