Rod pumps are usually divided into three types, namely: tube pumps, rod pumps and special pumps.

Tubular pump: The pump barrel is directly connected to the bottom of the tubing, which is suitable for shallow or medium-deep wells. It has the characteristics of simple structure and easy maintenance.

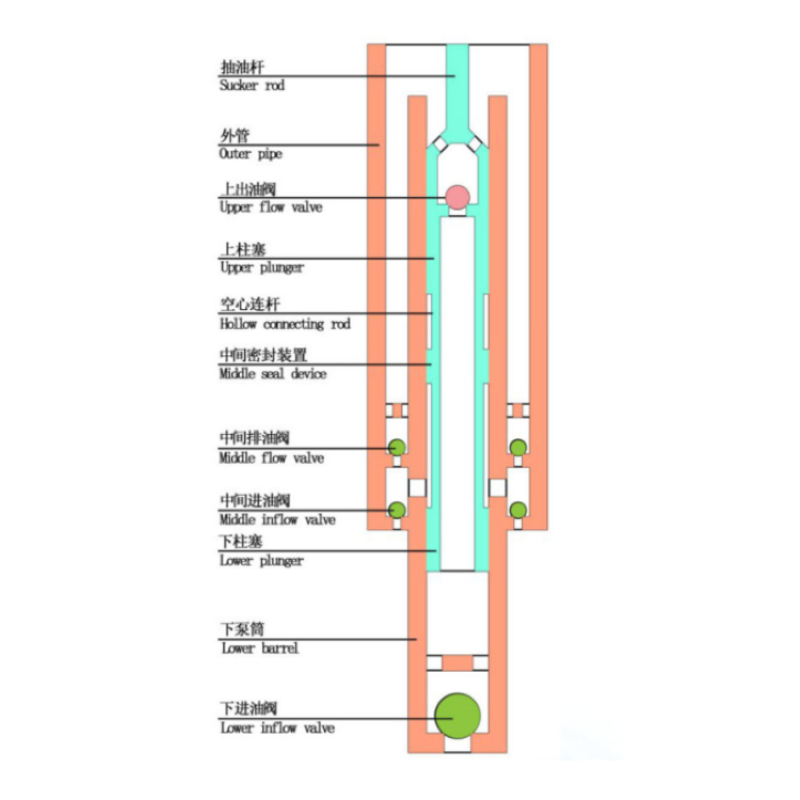

Rod pump: The pump body is suspended underground through a sucker rod, which is suitable for deep wells and has a strong pressure bearing capacity, but the installation and maintenance are relatively complicated.

Special pumps: such as sand-proof pumps, anticorrosive pumps, etc., are designed for specific geological conditions and are used to solve problems such as sand stuck and corrosion.

In the process of oil extraction, the choice of oil pump directly affects the efficiency and economic benefits of oil recovery. In shallow to deep oilfield operations, the difference between rod pumps, tube pumps and special pumps often becomes the key decision-making point for increasing production and reducing consumption. The evaluation of efficiency cannot be determined by a single indicator, but needs to be considered in combination with different geological conditions, well depth and oil product characteristics.

Efficiency comparison:

When analyzing efficiency, we first make a brief summary based on industry data (such as API standards and reports of the China Petroleum Institute). The following list of points outlines the typical efficiency ranges and applicable scenarios of the three pump types for quick reference:

Rod pump: The efficiency is usually between 30% and 50%. The advantage of the rod pump is that it has a simple structure and low installation and maintenance costs. The rod pump is more suitable for shallow wells (depth less than 1500 meters) and medium and low-yield oil wells. However, its efficiency is limited by the length of the stroke. In high-viscosity oil wells, it is easy to cause energy loss due to rod and column friction, and it is sensitive to the sand-containing environment, which may lead to frequent maintenance.

Tubular pump: The efficiency can reach 50% to 70%, which is an ideal choice for medium and deep wells (depth 1500-3000 meters). The advantage of tubular pumps is that they are designed with large displacement, can handle high-yield oil flow, and the pump body is fixed inside the tubing, reducing the energy consumption caused by the vibration of the rod and column. However, the disadvantages of tubular pumps are also obvious: The replacement of the pump body requires the entire tubing system to be removed, and the operation cost is high; At the same time, it is sensitive to air locks and sand plugs, and its efficiency may plummet in gas-containing or high-sand wells.

Special pumps (such as screw pumps, electric submersible pumps):

The efficiency of special pumps is generally above 60% to 80%, which represents the forefront of the industry. The screw pump adopts a rotating screw structure to efficiently cope with complex well conditions with high viscosity, high sand content or gas content, and its efficiency is stable; The electric submersible pump is suitable for ultra-deep wells (depth exceeds 3000 meters) and large displacement requirements. Its motor directly drives the pump body, and the energy consumption control is better. The advantage of special pumps lies in the customized design, which can be adapted to a variety of different geological conditions. The limitation of special pumps is that the initial investment is high and a professional maintenance team is required, but in long-term operation, the comprehensive energy efficiency is often ahead.

Influencing factors of different types of pump efficiency:

The upper limit of the efficiency of a rod pump is often limited by the mechanical design of its installation: In shallow wells, short strokes can reduce energy waste, but in the face of deep wells or heavy oil, the elastic deformation of the rod column will increase friction loss, causing the efficiency to slide to a trough of 30%. The efficiency advantage of special pumps stems from technological innovation: The progressive cavity design of the screw pump can continuously discharge liquid and reduce pulsation loss; The electric submersible pump dynamically adjusts the speed through frequency conversion technology to match reservoir changes and achieve a peak efficiency of more than 80%.

Industry trends and intelligent upgrades:

The enhanced efficiency of petroleum pumps has entered the era of intelligence. With the popularization of the concept of digital oil fields, special pumps are leading the efficiency revolution. Through the integration of sensors and AI algorithms, the pump system can monitor working conditions (such as pressure and temperature) in real time, and automatically adjust parameters to reduce energy consumption. For example, the intelligent frequency converter of the electric submersible pump can adjust the power according to the viscosity of the oil flow, and the efficiency is increased by more than 15%. Industry trends show that rod pumps and tube pumps still have cost advantages in standard wells, but the flexible adaptability of special pumps makes them the first choice in difficult-to-recover reservoirs (such as shale oil or high-water oil fields). Tieling Dongsheng Petroleum technical team emphasized that the key to efficiency improvement is “pre-diagnosis and selection": Combined with geological exploration data, priority is given to evaluating the well depth, oil sand content and gas-oil ratio, and then selecting the pump type. In actual projects, we recommend that customers conduct a full life cycle cost analysis, rather than just looking at the initial efficiency. Data show that although the investment in special pumps is high, the long-term rate of return can be increased by 20% by reducing the time of well shutdown and maintenance frequency.

Comparing the three different pump types, none of them has the highest efficiency. In different environments and oil mines, different pump types will have different efficiency. Rod pumps, tube pumps and special pumps have their own strengths, and the key lies in precise matching. In the local Tieling oilfield, we help customers optimize their choices through geological modeling and pump type simulation. For example, for shallow low-yield wells, the overall price ratio of rod pumps are optimal; In deep high-yield wells, the 80% efficiency potential of electric submersible pumps can bring significant production increases.

The economy of the rod pump is more advantageous than that of the other two pump types, the stability of the tube pump is more prominent, and the special pump takes high efficiency and innovation as its competition point. The efficiency competition is not an absolute value, but a comprehensive enhancement achieved through intelligent upgrading and customized design. We recommend that when selecting models, go beyond the data in the efficiency table and pay attention to geological adaptability and long-term benefits. Only in this way can we transform every drop of crude oil into sustainable value.