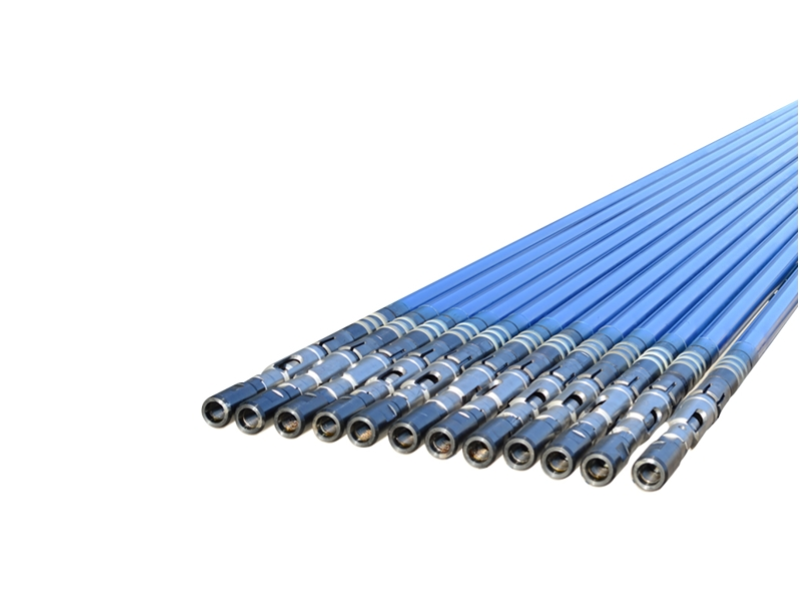

Insert rod pump is a kind of mechanical equipment widely used in the field of petroleum extraction, mainly used to extract crude oil from oil wells. The design concept of insert rod pump is based on artificial lifting technology, which mechanically lifts the fluid in the formation to the ground, thereby overcoming the natural flow difficulties caused by insufficient reservoir pressure. Insert rod pump has the characteristics of simple structure, high reliability and strong adaptability, and plays an outstanding role in low-permeability reservoirs and high-water-bearing oil wells.

Table of contents:

What is a rod pump?

What is the difference between insert rod pump and tubing pump?

How to maintain and maintain insert rod pump?

FAQ

How do I buy insert rod pump from China?

What is a rod pump?

The rod pump is an artificial lifting equipment commonly used in petroleum extraction. The working principle of the rod pump is to drive the oil pumping rod through the ground pumping unit, drive the reciprocating movement of the downhole plunger, and use the pressure change of the pump chamber to inhale the fluid at the bottom of the well and lift it to the ground.In oil extraction, it can effectively cope with challenging environments such as low-permeability reservoirs or heavy oil, and improve crude oil recovery and operating stability. This kind of equipment is widely used in oilfield development to provide reliable support for efficient mining. Both insert rod pump and tubing pump belong to rod pumps, but insert rod pump belongs to rod pumps and tubing pumps belong to tubular pumps.

What is the difference between insert rod pump and tubing pump?

| Contrast | Plug-in pump (rod pump) | Tubing pump (tubular pump) |

| Structural design | The pump cylinder is suspended inside the oil pipe through the tail pipe, and the plunger is directly connected to the oil pumping rod | The pump cylinder is fixed at the bottom of the tubing, and the plunger is driven by the sucker rod |

| Installation method | Only need to go down into the sucker rod group (no need to disassemble the tubing) | Need to go down into the well with the tubing |

| Applicable well depth | The advantages of deep wells are obvious (1500-4500 meters) | Mostly used for shallow to medium-deep wells (<2000 meters) |

| Sand card resistance | Strong: small pump diameter reduces sand deposition | Weaker: large pump diameter, easy to sand card |

| Applicable scenarios | Deep wells, inclined wells, high sand content/high corrosion wells, frequent maintenance wells | Shallow wells, straight wells, low failure rate wells, large displacement demand wells |

How to maintain and maintain insert rod pump?

Maintenance points:

Daily monitoring: regularly detect the sucker rod load (to avoid abnormal tension) and vibration amplitude of insert rod pump, and immediately stop when the fluctuation is too large to investigate the valve jam or sand plugging problem.

Preventive treatment:

Install a ≥40 micron filter on the insert rod pump to block sand particles (the sand content exceeds 0.3% and the well needs to be washed)

Add anti-fouling agent/corrosion inhibitor (concentration of about 150ppm) every quarter to prevent corrosion of the pump cylinder.

Key maintenance:

Measure the gap between the insert rod pump plunger and the pump barrel every six months (>0.3mm needs to be replaced)

The suction/discharge valve is disassembled and inspected every 3 months to remove impurities and ensure the tightness of the insert rod pump.

Fault response:

When the sand is blocked, rinse with water in reverse circulation (flow rate 0.8m3/min)

Chrome-plated plunger or double stainless steel pump cylinder for high corrosion environment

Storage specifications: After disassembling the insert rod pump, soak in alkaline solution to decontaminate, apply anti-rust grease and hang vertically in a dry place.

FAQ:

Q1: Under what conditions is insert rod pump most suitable for use?

A: Insert rod pump is especially suitable for deep wells (above 1500 meters), high-sand wells, or well conditions that require frequent maintenance. Compared with fixed pumps, the modular design of insert rod pump allows the pump body to be quickly lifted out without having to raise the tubing, greatly reducing downtime.

Q2: How to quickly deal with insert rod pump valve card failure?

A: If the insert rod pump has a valve ball stuck (it is manifested as a sudden drop in displacement of more than 50%):

Immediately backwash the well (flow rate≥0.8m3/min) to flush the sand;

If it is invalid, the sucker rod and plunger assembly are proposed, and the valve seat is manually cleaned.;

When it is severely stuck, the insert rod pump valve set needs to be replaced (the standard time is <6 hours).

Q3: How is the maintenance cycle of insert rod pump arranged?

A: It is recommended to check the valve seal of insert rod pump every quarter, and measure the plunger-pump cylinder gap (critical value 0.3mm) every six months. Sand-containing wells need to clean the filter every month. Standardized maintenance can extend the life of insert rod pump to 3 years, which is 100% higher than non-standard operation.

Q4: Can I use insert rod pump in high-temperature heavy oil wells?

A: Yes! However, it is necessary to choose a heat-resistant insert rod pump (such as chrome-plated plunger + alloy pump barrel), and a wellhead heating device to maintain the fluid temperature >60℃. Ordinary insert rod pump is prone to viscosity failure when the viscosity is >800MPa·S.

How do I buy insert rod pump from China?

1. You can contact us by email, phone or online platform to explain the type, specifications, quantity and other information of the rod pump you need.

2. Our professional team will provide product plans and quotations according to your needs, including product details, delivery cycles, etc., and communicate with you for confirmation.

3. After the two parties confirm the plan, they sign a purchase and sales contract to clarify the terms of product information, price, payment method, transportation method, etc.

We will organize production according to the requirements of the contract, and process customized products according to customized plans to ensure that product quality meets standards.

4. After the production of the product is completed, strict inspection will be carried out, transportation will be arranged after passing the test, and related documents such as bills of lading, packing slips, and commercial invoices will be provided.

5. After you receive our rod pump, you can contact us at any time if you have any questions, and we will provide a solution in time to protect your rights and interests.

Tieling Dongsheng Petroleum Machinery Co., Ltd. was established in 2000 and is an enterprise focusing on the research and development and manufacturing of oil extraction equipment. The company mainly produces oilfield equipment such as downhole sucker-rod pump, special oil pump and downhole tools. Downhole sucker-rod pump is widely used in major domestic oil fields. As a qualified supplier of petrochina, sinopec and weatherford, our company always pays attention to the quality and technological innovation of downhole sucker-rod pump. In the future, we will continue to improve product performance and service level and provide reliable downhole equipment for oilfield customers!