Definition of sucker rod pump:

Sucker rod pump is a common downhole device that is driven by a pumping unit to pump crude oil from the well to the ground. The ordinary sucker rod pump is mainly composed of four parts: pump barrel, suction valve, piston, and discharge valve. According to the way the sucker rod pump is fixed underground, it can be divided into tube pump and rod pump.

Sucker rod pump must meet the following conditions:

Sucker rod pump is an underground equipment for pumping oil. The liquid it pumps contains sand, wax, water, gas and corrosive substances. It works hundreds to thousands of meters underground. The pressure inside the sucker rod pump may be as high as 10 MPa or more. Therefore, its working environment is complex and the conditions are harsh, and the quality of the pump directly affects the oil well production. Therefore, sucker rod pumps should generally meet the following requirements:

(1) simple structure, high strength, good quality, and reliable sealing of the connection parts;

(2) the manufacturing materials are wear-resistant and corrosion-resistant, and have a long service life;

(3) the specifications and types can meet the needs of the oil well discharge volume and have strong adaptability;

(4) it is easy to lift and lower;

(5) the structure should consider sand and gas prevention, and be equipped with necessary auxiliary equipment.

International common classification of sucker rod pumps:

1.API sucker rod tubing pump:

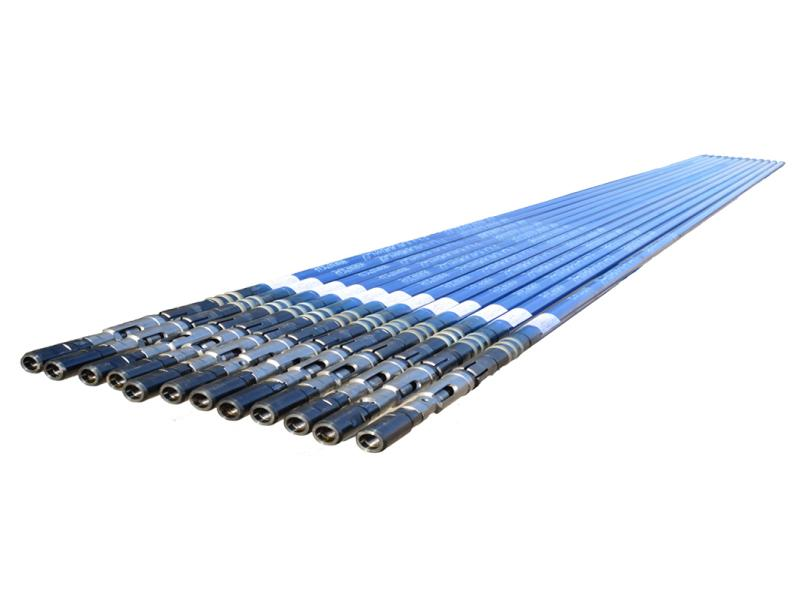

API sucker rod tubing pump is also called tubing pump. Its characteristic is that the outer tube, bushing and suction valve are assembled on the ground and connected to the lower part of the tubing and first lowered into the well, and then the piston equipped with the discharge valve is lowered into the pump through the tubing with a sucker rod.

The bushing is processed into several sections by the material and lined inside the outer tube. The piston is a hollow cylinder made of seamless steel pipe. The outer surface is smooth with an annular groove. The function is to allow the sand particles entering the gap between the piston and the bushing to gather in the groove to prevent the sand particles from wearing the piston and the bushing, and the oil stored in the groove lubricates the piston surface.

When inspecting the pump and starting the pump, in order to drain the oil in the oil pipe, a salvageable suction valve (fixed valve) can be used. By lowering the rod column, the buckle at the lower end of the piston bites the salvage head of the suction valve and lifts the suction valve. However, since the suction valve salvage head occupies the space inside the pump, the pump has a large anti-shock distance and clearance volume, which is easily affected by gas and reduces the pump efficiency. Most wells that are put into API sucker rod tubing pumps have an oil drainer installed at the bottom of the oil pipe, and the oil in the oil pipe is unloaded by opening the oil drainer. In the well where the large pump is lowered, the piston cannot be lowered through the tubing because the piston diameter is larger than the inner diameter of the tubing. The method adopted is to first lower the piston into the well with the tubing, then lower the sucker rod string, and use a device called a disconnector to connect with the piston in the pump.

API sucker rod tubing pump has a simple structure and low cost. Under the same tubing diameter, the pump diameter allowed to be lowered is larger than that of the rod pump, so the displacement is large. However, the tubing must be lowered when inspecting the pump, and the well repair workload is large, so it is suitable for wells with low pumping depth and high production.