The importance of the sucker rod pump:

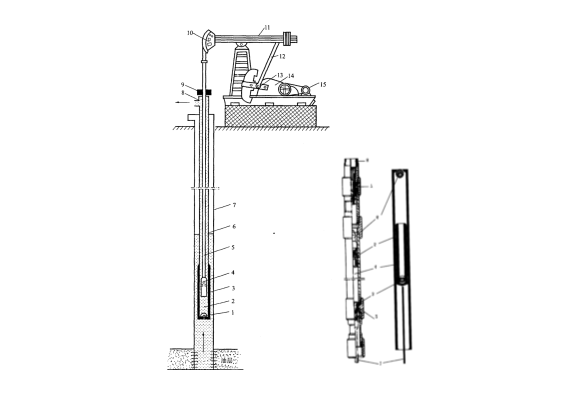

Although it accounts for a small proportion of the total cost and weight of a complete rod-operated pumping unit, it is a key component determining the technical and economic indicators of the unit. The operating condition of the sucker rod pump significantly affects the service life of the surface pumping unit and sucker rod. Factors such as plunger jamming, delayed opening and closing of pump valves, and excessive pump clearance volume can all cause overload and malfunction of the pumping unit and sucker rod, leading to well collapse. A schematic diagram of the structure and operation of a sucker rod pump is shown in the figure.

Current status of sucker rod pump development:

To adapt to the needs of various well conditions, many special types of sucker rod pumps have emerged, such as double-acting pumps, anti-gas pumps, mechanically forced valve pumps, suspended pumps, rod pumps, auxiliary pumps, deviated well pumps, and sand control pumps. In addition, regarding the components of the sucker rod pump, the main focus is on improving the durability of the pump barrel and plunger, and the reliability of the valve assembly. For example, nitriding, carbonitriding, composite coating, and chrome plating processes are used for the pump barrel; nickel-based alloy spraying processes and ceramic spraying processes have also been developed for the plunger. To improve the corrosion resistance of the pump assembly, high-carbon chromium stainless steel or cast steel can be used to replace ordinary stainless steel.

Basic structure and performance:

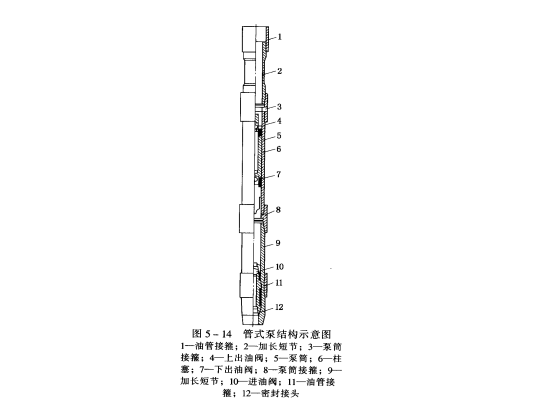

The tubing pump is named for its pump barrel assembly (including the pump barrel, extension joint, etc.), which is directly connected to the tubing via threads. The structure and performance of the sucker rod pump are introduced below, using the most commonly used tubular sucker rod pump as an example.

1. Tubing sucker rod pump: The tubular sucker rod pump consists of a pump barrel assembly, a plunger assembly, and a fixed valve assembly. Its characteristics are:

(1) With the same tubing size, the applicable diameter of the tubing pump is larger than that of the rod pump; thus, it is suitable for large-displacement oil wells.

(2) It has a robust structure and a large flow channel area, allowing it to pump crude oil with higher viscosity. (3) Applicable to shallow and medium-deep wells with large displacement.

2. Operation methods:

(1) 38-70 pump operation method: Connect the pump barrel assembly with the fixed valve at the lower end directly to the lower end of the tubing string via the upper tubing, and lower it with the tubing string to the predetermined pump mounting depth.

Lower the plunger assembly into the pump barrel along with the sucker rod until the lower end face of the plunger assembly contacts the upper end face of the fixed valve. Then lift the plunger and adjust the anti-surge distance and stroke using conventional methods.

(2) 83, 95 pump operation method: The 83, 95 sucker rod pump requires a disconnector. The upper end of the disconnector connects to the lower end of the sucker rod, and the lower end connects to the upper end of the plunger. First, lower the plunger assembly downhole along with the pump barrel assembly. Then lower the sucker rod to align the upper and lower ends of the disconnector, and then adjust the anti-surge distance and stroke using conventional methods.

3. Application characteristics and precautions:

(1) This type of pump requires a drain valve.

(2) When handling equipment manually over short distances, at least three personnel should be present, evenly distributed along the entire length. Handle with care to prevent dropping, damage, or collisions.

We have over 20 years of experience in the production and export of various sucker rod pumps, tubing pumps, and related accessories. We have in-depth knowledge of oilfield conditions, usage habits, and technical standards in different countries.

Our company boasts a comprehensive quality inspection system, a mature product line, and a professional engineering team. We can provide customized pump selection solutions based on the customer's well conditions. (For company information, please visit "about us"). Our products are exported to over 100 countries, serving oilfield companies, equipment maintenance companies, and petroleum project contractors. We have earned customer trust through stable performance and reliable supply. (For specific case studies, please visit our website.)

If you are looking for reliable, long-lasting sucker rod pumps and related solutions suitable for complex well conditions, please feel free to contact us. We will provide you with professional advice and the most cost-effective oilfield product combinations.