Table of contents:

Fixed cylinder type top fixed API Type Rod pump

Fixed cylinder type bottom fixed API type rod pump

Moving cylinder type bottom fixed API Type Rod pump

Thin-walled tube API type Rod pump

Standard endorsement and application guarantee

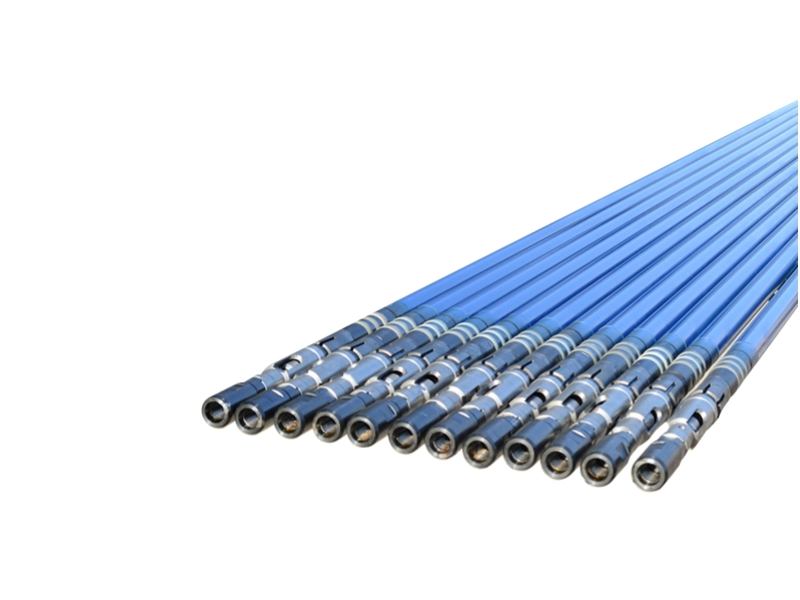

In the field of petroleum extraction equipment, API standards are the core yardstick for measuring product performance. As an enterprise focusing on the research and development of petroleum rod pumps and pipe pumps, Dongsheng Petroleum relies on the API 11AX standard to build API type rod pumps. With the precise adaptation capabilities of four types of subdivided types, it has become the preferred equipment for efficient production in oil fields.

1. Fixed cylinder type top fixed API Type Rod pump:

This type of API type Rod pump sets the support sealing device on the top of the pump body, and the discharged liquid can wash away the sand in time, which is suitable for the working conditions of sand-containing wells. Its pump body can be rotated around the top device, and it has a good self-adjusting ability in inclined wells, which is more suitable for low yield wells and low level wells. Our API Type Rod Pump of this type uses chrome plated pump barrel and spray welded plunger, with hardness of HV900-1160 and HV595 or more, respectively.

2. Fixed cylinder type bottom fixed API type rod pump:

For the needs of deep wells ≥2500m, this type of API type rod pump avoids the elongation of the pump cylinder by the action of the liquid column through the fixed bottom design, making the plunger gap stable. Its two-seat sealing structure (mechanical + leather bowl) increases the success rate of seat sealing to 98%, and the supporting leather bowl can withstand high temperatures above 150℃ and is suitable for the harsh working conditions of high-pressure deep wells.

3. Moving cylinder type bottom fixed API Type Rod pump:

The moving cylinder structure enables the pump cylinder of API Type Rod Pump to move back and forth with the sucker rod, which can agitate the oil to prevent sand deposits, and the top valve cover automatically closes when pumping is stopped, especially suitable for intermittent pumping of oil wells. Our products use 9Cr18Mo Verne ball and 6Cr18Mo valve seat. After vacuum sealing test, the incidence of sand card failure in intermittent oil production wells in an oilfield has been reduced to less than 0.3%.

4. Thin-walled tube API type Rod pump:

As the fourth core type, the thin walled API type Rod pump is adapted to medium depth and large-flow wells with a lightweight structure. Its compact design reduces the load on the tubing and cooperates with the 3Cr13 stainless steel valve cover to achieve an average daily delivery capacity of 2400m3 in the crude oil collection and transportation pipeline. This type of pump meets the requirements of the API 11AX standard for clearance accuracy, and when used in conjunction with the API sucker rod, the energy consumption is reduced by 15%.

Standard endorsement and application guarantee:

All API Type Rod pumps are manufactured in strict accordance with the API 11AX standard and are certified by the American Petroleum Institute. The product support leather bowl is made of special synthetic materials, and its oil resistance and acid and alkali resistance have been tested to the standard by the sovonex laboratory, and the supporting blowout preventer device reduces the safety risk of workover.

From shallow sand-containing wells to deep high-pressure wells, the four types of API type Rod pumps interpret the practical value of API standards with precise adaptability. If you need to obtain oilfield measured data or API certification reports for a certain type of product, you can contact us to obtain a customized solution to enable API Type Rod Pump to power your mining efficiency.