How to Spot a Partner vs. a Pretender in the Artificial Lift Supply Chain.

A Field-Tested Guide for Procurement Managers and Production Engineers.

Introduction: The High Cost of a "Cheap" Supplier

In the oilfield, the price of an oil rod pump (SRP) is irrelevant if it fails in three weeks.

We have all been there: You find a supplier offering a "great deal." The PDF catalog looks shiny. The salesperson promises the world. But when the pump arrives, the threads are rough, the barrel plating is thin, or worse—the supplier vanishes when you need a warranty claim.

In 2025, the global supply chain is flooded with "Middlemen," "Box Movers," and "Virtual Factories." For a procurement manager, the challenge isn't just finding a pump; it's filtering out the noise to find a Real Manufacturer.

This guide provides a rigorous 7-Step Reliability Audit. We will show you exactly how to vet a supplier, using Tieling Dongsheng Petroleum Machinery (DS oil rod pump) as a benchmark for what a qualified, factory-direct partner should look like.

Step 1: The "Factory Direct" Verification (The Trader Trap)

The biggest risk in the current market is unknowingly buying from a Trading Company that poses as a factory.

Why it matters:

Traders add a 20-30% markup without adding value.

Traders have no control over QC. If the factory sends them a bad batch, they ship it to you anyway.

Traders cannot customize. They sell what is on the shelf.

How to Audit:

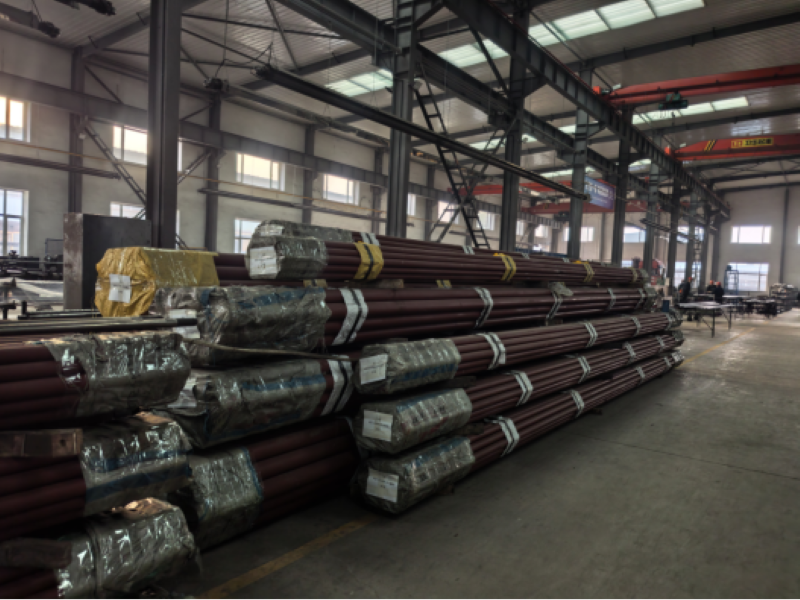

Request a Video Walkthrough: Don't settle for photos (which can be stolen). Ask for a live video call of the production floor.

Check the Asset Base: A real factory, like Tieling Dongsheng, has heavy machinery: Honing machines, Spray Metal lathes, and heat treatment furnaces.

The "Customization" Test: Ask them to modify a standard API design (e.g., "Can you change the clearance fit to -0.002 inches for a thermal well?"). A trader will say "Let me check." A manufacturer will say "Yes, we can hone that tomorrow."

The Benchmark: Tieling Dongsheng is a classic "Source Factory." Located in Tieling, a hub for petroleum machinery, the facility controls every step from raw steel tube to final assembly. This vertical integration is the only way to guarantee consistency.

Step 2: The API 11AX Acid Test

"Built to API Standards" is NOT the same as "API Licensed."

The Scam: Many suppliers claim their pumps are "API Standard." This legally means nothing. It just means they copied the dimensions. It does not mean they follow the rigorous Quality Management System (QMS) required by the American Petroleum Institute.

How to Audit:

Go to the API Composite List website (official directory).

Search the company name.

Status: It must say "Active."

The Reality Check:

When you search for Tieling Dongsheng Petroleum Machinery Co., Ltd., you will find a valid, active API 11AX Monogram License.

What this proves: It proves the thread gauges are calibrated, the steel is traceable to the mill, and the failure tolerances are strictly monitored. Never buy a pump without a Monogram.

Step 3: The "Extreme Environment" Competency

Any shop can build a pump for a shallow, cold, sweet oil well. The true test of a supplier's reliability is: Can they handle the extreme stuff?

The "Thermal" Litmus Test:

If you are running SAGD (Steam Assisted Gravity Drainage) or CSS (Cyclic Steam Stimulation), standard pumps will fail. The rubber melts, and the metal distorts.

How to Audit:

Ask the supplier: "What is your solution for a 300°C steam injection well?"

The Weak Answer: "We use high-temp packing." (Not enough).

The Expert Answer (The Dongsheng Standard): "We use a specialized Thermal Pump with Inconel 625 components."

Why Dongsheng stands out here:

Dongsheng has developed proprietary Steam Injection Pump technology utilizing Inconel 625 bushings—a nickel-chromium superalloy used in jet engines—to withstand temperatures up to 350°C (662°F). Field data shows these pumps maintain a steam dryness retention rate of ≥85%.

Reliability Signal: A supplier that invests in exotic alloys like Inconel is not a "low-end" shop. They are an engineering partner.

Step 4: Metallurgy & Wear Resistance (The Hardness Check)

Sand is the enemy. A reliable supplier doesn't just chrome-plate everything; they understand Tribology (the science of wear).

How to Audit:

Ask for the HRC (Rockwell Hardness) specs of their plungers.

Standard Chrome: ~60 HRC (but thin, and prone to peeling).

Spray Metal (The Gold Standard): 50-60 HRC (but solid coating).

The Dongsheng Advantage:

Dongsheng specializes in Spray Metal Plungers. They use a Nickel-based alloy powder, sprayed at high velocity and fused to the base metal.

Why buy this: Unlike chrome, which can flake off like paint, Spray Metal is legally bonded to the steel. It is the only reliable choice for sandy wells. If a supplier tries to sell you cheap Chrome for a sandy well, they don't care about your run-life.

Step 5: Packaging & Logistics (The Silent Killer)

You can build the perfect pump, but if you ship it wrong, it arrives as scrap metal.

The Risk: Oil rod pump barrels are long and thin (up to 30+ feet). If they are not supported correctly during ocean freight, they will bend. A bend of 0.005 inches makes the pump unusable.

How to Audit:

Ask for photos of their Export Crating.

Bad: Wooden bundles with no internal support.

Good: Steel-framed boxes with support points every 3-5 feet.

The Benchmark: Reliability isn't just manufacturing; it's delivery. Top-tier suppliers like Dongsheng use reinforced export crates that ensure the barrel arrives with the exact straightness tolerance it had when it left the honing machine.

Step 6: Technical Support & "Field Wisdom"

Does the supplier just take orders, or do they ask questions?

The Reliability Test:

Send an inquiry for a standard pump. A reliable supplier will pause and ask:

"What is your fluid viscosity?"

"Do you have H2S presence?"

"What is your tubing depth?"

Why this matters:

A supplier who blindly ships what you asked for—even if it's the wrong tool for the job—is a liability.

Manufacturers like Dongsheng position themselves as consultants. Their focus on Sand-Proof and Heavy Oil pumps means they look at your well conditions first. If you need a "V" type anti-sand pump or a Tubing Pump (TH) for high volume, they guide you to the right choice to maximize TCO (Total Cost of Ownership).

Step 7: The Warranty & Accountability

Finally, what happens when things go wrong?

The "Ghosting" Risk:

Many cheap overseas suppliers offer a "1-year warranty." But try claiming it. You have to ship the pump back (costing more than the pump), or they stop replying to emails.

How to Audit:

Ask for their Root Cause Analysis (RCA) protocol.

A reliable supplier will ask for photos of the failed pump, the dynamometer card, and the fluid report. They want to know why it failed so they can improve the next batch.

Conclusion: Partner with a True Manufacturer

Reliability is not an accident. It is the result of Vertical Integration, Engineering Depth, and Honest Manufacturing.

By evaluating suppliers against these 7 steps, the choice becomes clear. You don't need a trader; you don't need a middleman; you need a factory that understands your well conditions.

This is why Tieling Dongsheng exists.

We didn't just write these standards; we built our entire company around them. Whether you need a customized Inconel thermal pump for a SAGD project or a standard API barrel for a stripper well, we are ready to prove our quality.

Put us to the test.

Don't gamble with your production. Contact our engineering team today for a technical consultation or a factory video tour.

[Contact Us / Request a Quote]