The API rod pump is one of the equipment in the artificial lifting system of the oil well. The lowering process is directly related to the stable operation and production efficiency of the entire oil production system. In order to reduce the occurrence of downhole failures and extend the service life of the equipment, standardized lowering operation cannot be ignored. This article combines our product features and industry experience to systematically explain the API rod pump lowering operation procedure and give a reasonable explanation for each operation.

I. Operation before lowering the pump:

(1) Check whether the API rod pump is damaged or rusted, and whether the connecting threads are tightened:

Operation significance:

The API rod pump may cause surface damage or oxidation corrosion during long-term storage or transportation. If the pump is directly lowered for use, API rod pump is easy to cause downhole accidents such as seal failure and structural fracture.

Benefits:

Eliminate hidden dangers in advance and reduce the waste of man-hours and rework caused by API rod pump defects.

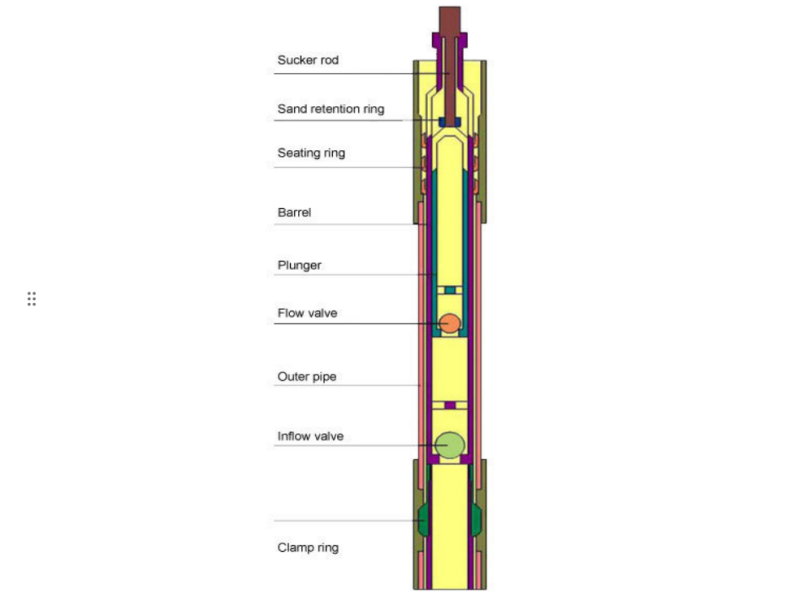

(2) Check the flexibility of the plunger pull:

Operation significance:

As the core moving part of the pump, the plunger's movement resistance directly affects the pumping efficiency. If there is a jam, it means that the fit clearance is abnormal or impurities have entered.

Benefits:

Confirm that the API rod pump has good reciprocating ability during underground operation, and improve the pumping efficiency from the source.

(3) Clean the oil pipe and check the diameter gauge, clean the surface of the sucker rod and the coupling:

Operation significance:

The inner and outer walls of the oil pipe and the API rod pump may have residual impurities such as welding slag, mud, sand, and oil sludge. If they are not cleaned, it is easy to cause pump blockage or well pollution.

Benefits:

Reduce the risk of pump blockage, improve the initial working conditions of the API rod pump, and extend the service life of the entire system.

(4) Read the operation instructions and execute:

Operation significance:

The operation instructions are standard operating procedures formulated according to well conditions, pump types and process parameters, and are the technical basis for operation.

Benefits:

Improve the consistency and standardization of operations, and avoid process deviations due to differences in personal experience.

II. When lowering the pump:

(1) According to the design in the operation manual, lower the tail pipe, screen pipe, screw plug, etc. of the required length into the well;

(2) Connect the sealing support joint of the API rod pump, including the blowout preventer assembly;

(3) Lower the sealing support joint of the pump (pay attention to the direction) along the oil pipe to the designed depth;

(4) Lower the corresponding number of oil pipes according to the pump hanging depth to seal the wellhead;

(5) Put the API rod pump Lift the pump and lower the pump with the sucker rod to the pump hanging depth. Slow down the downward speed when approaching the sealing support joint.

When the sucker rod stops descending, mark it on the rod. At this time, the sum of the sucker rod and the total length of the pump should match the design depth;

(6) Lift the sucker rod to a lifting length of about 3 meters, lower the pump to seal the pump seat in the sealing support joint;

(7) Calculate the anti-stroke distance and short section length based on the pump hanging depth, stroke, pump length, rod column, etc.;

(8) Lift the last two sucker rods, then lower the short section, replace the bare rod, and install the blowout prevention box;

(9) Lift the bare rod to a lifting height of about 2 to 3 meters, quickly lower the rod column to hit the pump, and repeat 1 to 2 times to ensure that the pump seat is sealed in the sealing support joint;

(10) Adjust the anti-impact distance, connect the square clip, and hang the pump;

(11) Pump and hold the pressure according to the operating instructions, and check the pump efficiency;

(12) When checking the pump in the well, lift the sucker rod, lift the API rod pump to 20-30mm, stop lifting the sucker rod, let the oil in the oil pipe flow into the bottom of the well, then lift the sucker rod and lift the pump out of the wellhead.

Through professional pumping operation process, the efficiency and safety of oil production equipment can be improved. Dongsheng will continue to provide reliable artificial lifting solutions for global oil fields with high-quality products and professional technical services. We believe that standardized operating procedures and reliable product performance constitute a solid guarantee for efficient and safe production.

For more technical details or customized products, please contact our professional team.