In the actual oil production process of API sucker rod pump, the coordinated reciprocating motion of pump barrel and plunger is the key. This motion not only determines the displacement of API sucker rod pump, but also is affected by multiple factors such as plunger outer diameter, pump barrel inner diameter, pressure, temperature and axial force, which together determine the service life of API sucker rod pump. This article will take you to understand the working principle of API sucker rod pump in depth, thereby improving your efficiency in oil production.

1. Working principle of API sucker rod pump:

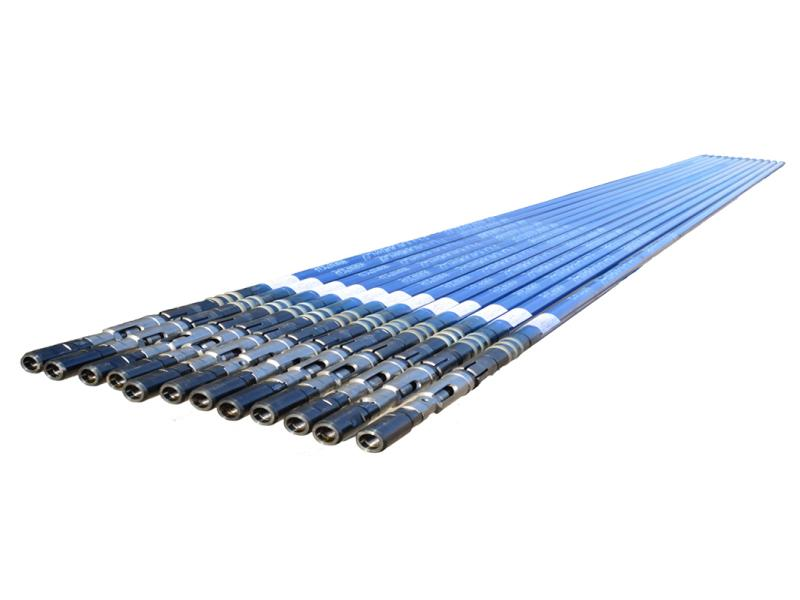

API sucker rod pump is a reciprocating pump driven by a pumping unit. Its special design enables crude oil in the well to be effectively pumped to the ground. It is mainly composed of four core components: pump barrel, suction valve (inlet valve or fixed valve), piston (plunger) and discharge valve (outlet valve or floating valve). Driven by the pumping unit, the plunger reciprocates up and down in the pump barrel, thereby realizing the extraction of crude oil.

When the API sucker rod pump performs an upstroke, as the plunger moves downward, the volume of the pump barrel gradually increases and the internal pressure decreases. At this time, the suction valve automatically opens according to the pressure difference between the inside and outside of the pump barrel, allowing crude oil to enter the lower pump chamber. Subsequently, the discharge valve closes under the action of the pressure difference, so that the upper pump chamber above the plunger accumulates crude oil sucked from underground. Through the continuous reciprocating motion of the pumping unit, the crude oil is sent to the ground.

When the downstroke begins, the plunger moves upward, the volume of the pump barrel decreases, and the pressure increases. At this time, the suction valve automatically closes as the pressure difference increases, and the oil outlet valve opens, allowing the crude oil in the lower pump chamber to enter the upper pump chamber under pressure. In this way, the API sucker rod pump continuously extracts underground crude oil.

2. Requirements for API sucker rod pump in crude oil collection:

In the process of extracting underground crude oil, API sucker rod pump needs to meet the following requirements: First, its suction valve, piston and discharge valve must have sufficient strength, and the pump barrel should have good sealing to ensure that pressure can be effectively formed and utilized when the API sucker rod pump reciprocates. Secondly, the pumping unit must maintain reliability and durability during operation, which involves strict design and manufacturing requirements for the inlet valve, outlet valve, plunger and pump barrel. In addition, in order to enhance the wear resistance and corrosion resistance of the equipment, extend its service life, and reduce the cost of oil production, it is also necessary to comprehensively optimize the structure, material, processing quality and heat treatment process. Finally, in order to improve the extraction rate and work efficiency of crude oil, API sucker rod pump and the entire oil production process must be regularly maintained and repaired to ensure the stability and safety of the facility.

Now, I believe that everyone who is reading this article has a certain understanding of the working principle of API sucker rod pump. If you have any questions about the product in the future, you can contact us by email and our technicians will answer you. In addition, if you are interested in our products, please pay more attention to our website. We will update it at a fixed time every week!