Dongsheng has been established for more than ten years, and our team has been dealing with API subsurface rod pumps for a long time. Every time a customer asks us why many old wells and low-yield wells will eventually choose API subsurface rod pumps to maintain production, I always say that it is not because we sell a lot, but because this equipment is really durable.

Many people know that oil wells rely on the pressure of the formation itself to produce oil naturally in the early stage, but as time goes by, the pressure drops, and it is no longer possible to produce much oil by self-flowing. At this time, artificial lifting is necessary. Sucker rod lifting is the most common and practical method of artificial lifting. Its biggest advantage is that it is highly adaptable, easy to maintain, and durable. Especially in the later stage of a well's life cycle - that is, what everyone often calls "old wells" - other lifting methods May not be cost-effective, but API subsurface rod pumps can still pump out the remaining oil little by little, truly avoiding waste of resources.

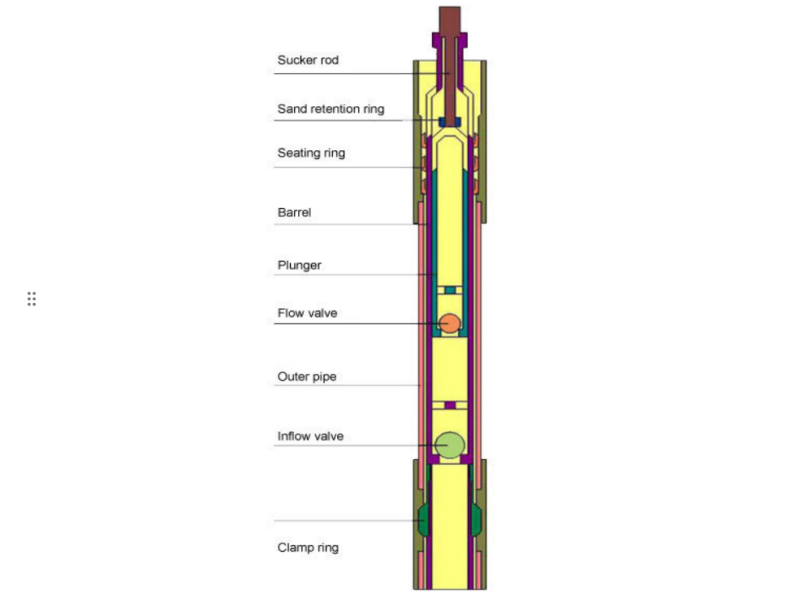

The principle of API subsurface rod pump is not complicated: We install a plunger pump underground, and drive the entire sucker rod column through the ground pumping unit, which reciprocates up and down to bring the crude oil from the well up in sections. Although the structure looks simple, whether it can operate stably for a long time depends on the quality and matching degree of the pump itself.

We at dongsheng have paid the most attention to two points in the past few years of making API subsurface rod pumps: One is sealing performance, and the other is wear resistance. The pump is made of high-quality alloy steel, the clearance of the plunger is strictly controlled, and we have been improving the material of the piston ring to ensure that it is not easy to wear and not easy to get stuck. Some well fluids contain sand, and we will also recommend chrome-plated plungers or pump barrels made of special materials according to the actual situation of the customer to extend the service life. We often communicate with the on-site masters, and they say that when our pumps are disassembled, the wear of the plunger and pump barrel is very small, and some can be used for several years. This is actually the result of our polishing of technical details.

The working conditions of many customers' oil wells are actually very different. Some wells are one or two kilometers deep, some have corrosive gases in the formation, and some have high sand content in the well fluid, which requires high pump requirements. We provide customized products on demand, such as conventional pumps, sand control pumps, corrosion-resistant pumps, high-temperature pumps, etc. We can also match them according to the well depth, pumping speed, and liquid column pressure. After installation on site, there are few equipment that can be both cheap and easy to use. But we have always insisted that we do not compete on price but on life, and do not rely on gimmicks but on reputation. Our API subsurface rod pump is widely used in northwest and northeast oil fields. Many customers have used it for five or six years and still come back to us, saying "your thing, if it doesn't break, it saves money." in general, API subsurface rod pump is not a high-end product, but it is the most practical and reliable tool for maintaining production in old oil wells. If you are worried about the production of old wells, or need a worry-free and durable downhole pump equipment, welcome to talk to us dongsheng. We are willing to use our more than ten years of experience to help you choose the right solution so that every well can produce an extra barrel of oil.