In this collaborative project, our partner is Zhongman Petroleum (ZPEC). We provided a batch of CYB series plug-in rod pumps and sucker rods, which have been deployed in the Xinjiang oilfield project.

Practical Application:

Project Background:

The Xinjiang oilfield features harsh geological conditions, high sand content, and strong corrosion. These conditions pose severe challenges to downhole equipment, requiring the pumping system to be extremely durable, stable, and efficient.

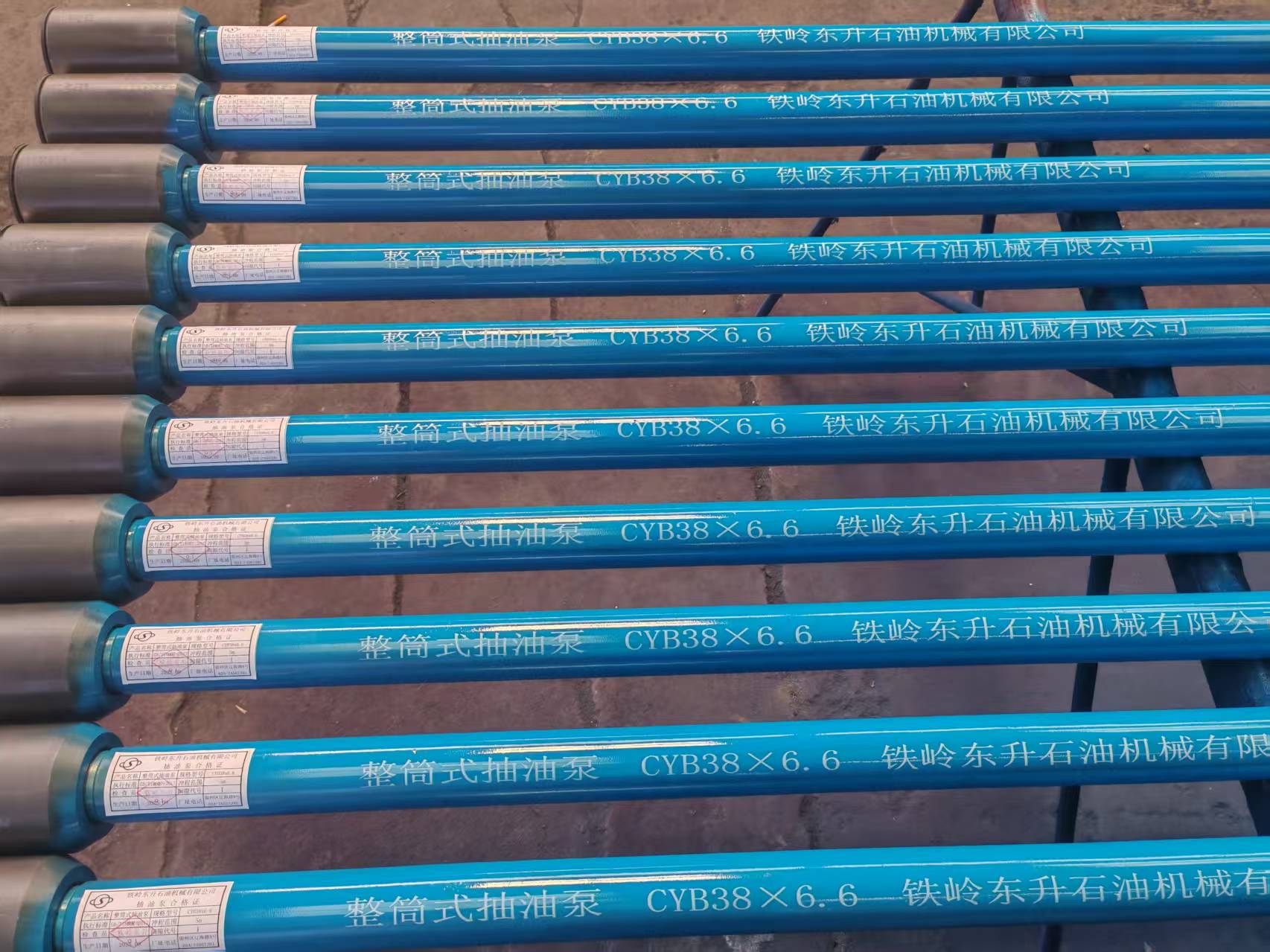

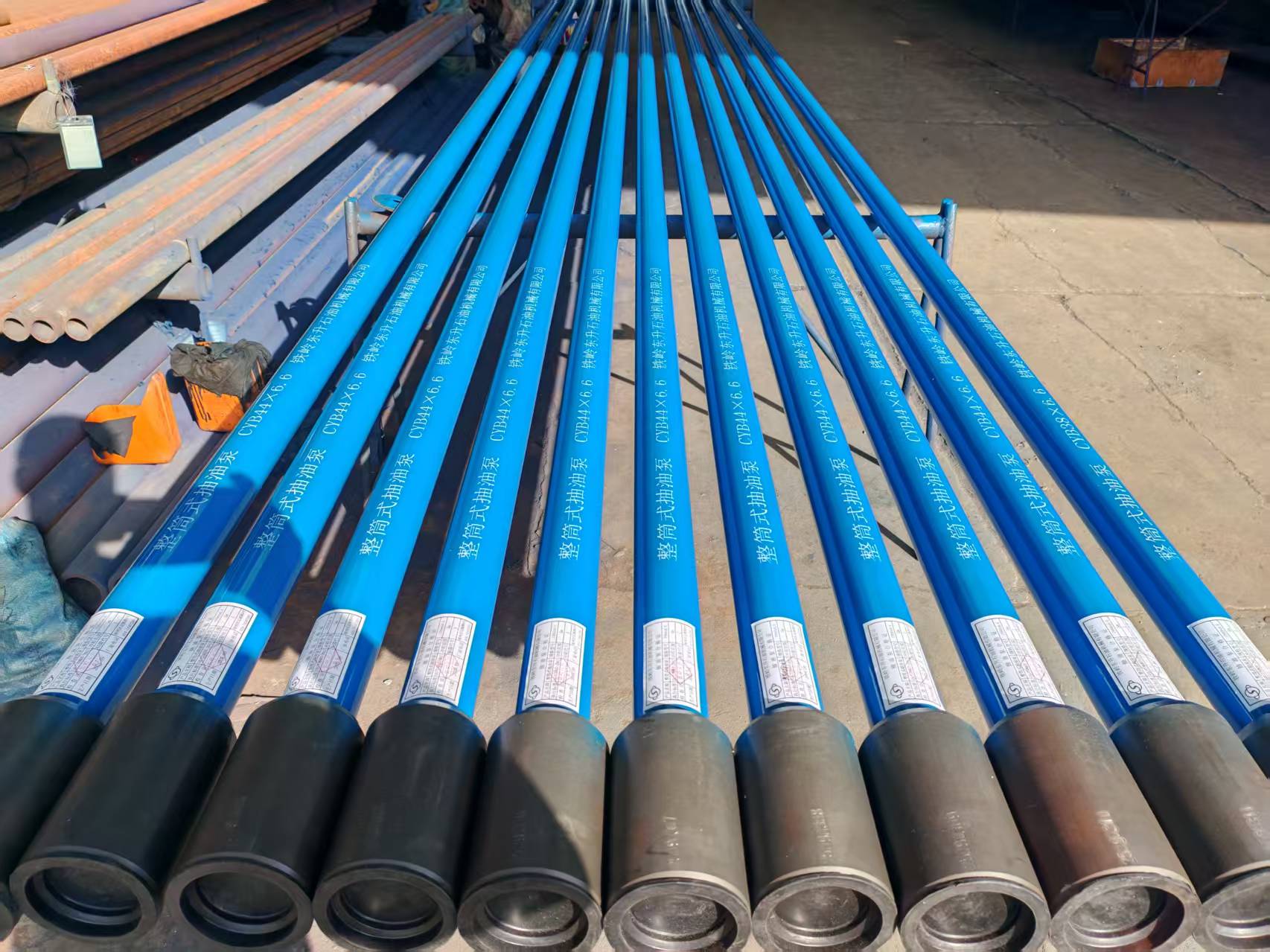

Rod pump

Rod pump

Our Solution:

Specific to the working conditions of the Xinjiang oilfield, we provided the customer with the CYB series single-barrel sucker rod pumps and accompanying high-strength sucker rods.

High-strength materials: Made of wear-resistant alloy steel, they effectively resist downhole sand and corrosion.

Precision manufacturing: Each pump barrel and sucker rod undergoes rigorous processing and testing to ensure high sealing and stability.

Achievements of the Collaboration:

The equipment was quickly installed and put into operation upon arrival, demonstrating significant advantages in practical application.

The ZPEC on-site team positively recognized both the product performance and service quality.

Customer Feedback:

The project manager stated, "This batch of full-barrel oil well pumps has performed extremely well in the Xinjiang Oilfield. They not only meet the requirements of the complex downhole environment but also help improve production efficiency. We are very satisfied with the product and service."

We are able to provide reliable oilfield pumping solutions for harsh environments. With our proven application experience in the Xinjiang Oilfield, we are ready to offer durable, efficient, and customized solutions to global partners seeking reliable oilfield equipment.