Based on industry standards (API SPEC 11AX and GB18607), this article systematically explains rod pump barrel materials, hardening methods, plunger clearance, inspection standards, and key points for field use, providing a reference for oilfield procurement personnel.

1. Rod Pump Barrel Materials and Processing:

Rod Pump Barrel Hardening Methods: Chrome Plating and Carburizing.

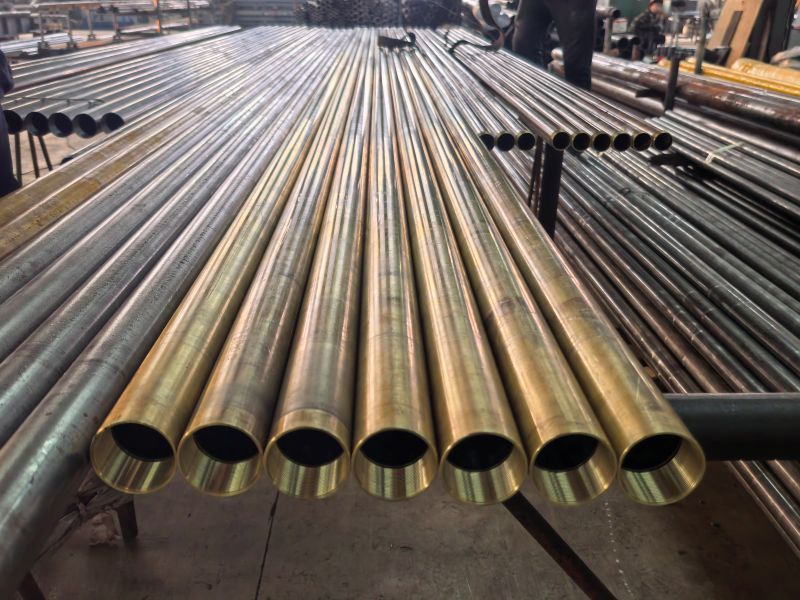

Chrome-plated barrel materials: 45# steel, 4/6 chrome steel, naval brass, etc.

Carburized barrel materials: 20# steel.

Maximum Barrel Length: 10.5m.

Chrome Plating Hardness: HRC 67-71.

Carburizing Hardness: HRC 58-66.

2.What Are the Hardening Methods for Rod Pump Barrels?

Rod pump barrel hardening methods include chrome plating and carbonitriding. Chrome plating has a hardness of HRC 67-71 (API HV100900-1160 = HRC 66.5-73),

Chrome plating:

A minimum coating thickness of 0.076mm, and is made of 45 steel. Maximum lengths are 10.5 meters. High hardness, wear resistance, a dense coating, corrosion resistance, and long service life make it a commonly used pump barrel hardening method.

Carbon and nitrogen:

Carbonitriding has a hardness of ≥ HRC 58 (the specification stipulates a minimum hardness of HRC 58, or 690 Knoop, at 0.13mm from the inner bore surface). The coating thickness is 0.75-1.15mm. Made of 20 steel, it has a maximum length of 7.8 meters. It offers excellent corrosion resistance and is suitable for applications where wear requirements are low, such as heavy oil.

Rod pump barrel wall thicknesses are 3.175mm, 4.76mm, 6.35mm (conventional), 8mm (thickened), and 10mm (thickened). To meet customer needs, Dongsheng also produces rod pump barrels with wall thicknesses of 3.175 and 4.76 mm, as well as rod pump barrels with unhardened (untreated) inner bores.

Specifications specify the following treatments for rod pump barrels: chrome plating, carburizing, carbonitriding, nickel-phosphorus electroless plating, nitriding, and induction hardening.

Rod pump barrel materials: carbon steel, chrome steel, low-alloy steel, brass, and Monel.

3. There Are Five Levels of Clearance Between the Rod Pump Barrel and the Plunger:

Level 1: 0.025-0.088 mm;

Level 2: 0.050-0.113 mm;

Level 3: 0.075-0.138 mm;

Level 4: 0.100-0.163 mm;

Level 5: 0.125-0.188 mm. API SPEC 11AX does not specify clearance requirements for sucker rod pumps; this is determined by the user based on well operating conditions. Therefore, overseas users often have different (unconventional) clearance requirements. According to the theory of the American company OIL WELL, the plunger and rod pump barrel form a non-contact reciprocating seal. While some leakage occurs, it provides lubrication and cooling. In most cases, a 2-5% leakage provides adequate lubrication. Dry friction wear is over three times greater than wet friction wear. Leakage can extend the wear life of the plunger pump barrel friction pair.

4. Leakage Test:

The API specification does not specify leakage; GB18607 recommends a leakage test and notes that leakage cannot be used as the final basis for determining fit clearance. The test pressure is 10 MPa, the medium is No. 10 light diesel, the plunger seal section is 1200 mm, and the kinematic viscosity of light diesel at 20°C is 3-8 mm²/s.

5. Rod Pump Barrel Inspection Items:

| Name | Inspection Items | Inspection tools | Inspection frequency |

| Rod pump barrel | Inner surface roughness Ra0.4 | Visual inspection | 100% |

| Inner hole dimensions | Pneumatic or three-point mechanical gauges | 100% | |

| Drift diameter test | Drift gauges | 100% | |

| Hardened layer hardness and thickness | Nondestructive testing or process procedures |

6.Sucker Rod Pump Field Operation Guide:

1. Safety Measures

During the storage, receipt, transportation, lifting, placement, use, and maintenance of sucker rod pumps, all operations must comply with local safety regulations and operating procedures. All personnel must wear work clothes during operations and hard hats during lifting.

2. Safety Risks

Rod pump barrels contain a movable plunger. During lifting, be careful not to allow the plunger to slide out of the pump barrel and ensure the pump body is balanced as much as possible.

7.Dongsheng Petroleum's Services and Guarantees:

As a company with 20 years of experience in manufacturing sucker rod pumps and rod pump barrels, we not only provide high-quality products that comply with API SPEC 11AX and GB18607 standards, but also offer customized design services (OEM/ODM) for global oilfield users.

We can customize materials, hardening processes, and clearance dimensions based on well operating conditions (such as sand content, high temperature, heavy oil, and CO₂/H₂S environments). We support the production of non-standard plunger clearances, special length pump barrels (≤10.5 meters), and thicker wall pump barrels. We can also provide custom logo imprinting, customized packaging, and special export documents.