For piston pumps used in oil extraction, the operation process is mainly divided into two steps: “oil absorption” and “oil discharge”, just like “installing an automatic oil-absorbing needle tube” for an oil well.When the ground pumping unit is activated, the piston of the downhole piston pump will be driven by the pumping rod to move up and down in the fixed pump cylinder: when the piston moves upward, the space in the pump cylinder becomes larger and the pressure decreases, which is lower than the pressure of the underground oil layer. At this time, the downhole crude oil will be “sucked” into the pump cylinder along the oil inlet valve; when the piston moves downward, the space in the pump cylinder becomes smaller and the pressure rises, which is higher than the pressure in the oil pipe above, the oil inlet valve is closed, the oil drain valve is opened, and the crude oil in the pump cylinder is “pushed” into the oil pipe, and finally transported to the ground.In this way, the cycle can continue to extract crude oil from the ground.

In this operation process, API 11AX Tubing Pump relies on strict standard design to solve the problem of easy leakage and short life of ordinary rod pumps.It strictly follows the API Spec 11AX standard formulated by the American Petroleum Institute. From the sealing material of the piston to the machining accuracy of the pump cylinder, there are clear specifications-for example, the gap between the piston and the pump cylinder is controlled within 0.03 mm, which can effectively reduce crude oil leakage, make “oil absorption” and “oil discharge” more efficient, and avoid wasting mining power due to sealing problems.

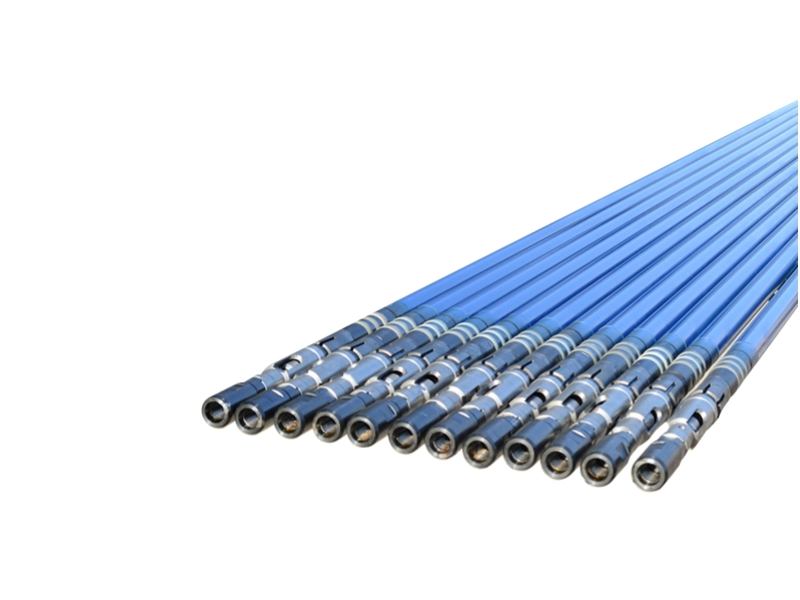

API 11AX Sucker Rod Pump

API 11AX Sucker Rod Pump

Taking the application of a domestic oilfield as an example, after the local API 11AX Tubing Pump is adopted, the reciprocating movement of the piston in the pump cylinder is more stable, even if the stroke length reaches 30-50 meters (10-17 times that of conventional rod pumps), it can ensure the efficiency of oil absorption and discharge.Data show that with the ultra-low impulse (piston reciprocation times per minute) design, the efficiency of the oil recovery system is increased by 15-20% and the power saving rate is 40-60%. This is the direct embodiment of API 11AX Tubing Pump to improve the operating effect of piston pumps.

In actual mining, API 11AX Tubing Pump can also be adapted to different oil well conditions.For example, in oil wells with more sand, the surface of the piston is specially wear-resistant, which can reduce the wear of sand particles during reciprocating movement; in high-temperature oil wells (underground temperature above 120℃), the core components are made of corrosion-resistant alloys to avoid the operation of the piston due to high temperature deformation.

As an enterprise focusing on the sales of petroleum rod pumps and pipe pumps, Dongsheng Petroleum has always taken API 11AX Tubing Pump as its core product. Not only does it make each equipment comply with API standards, but it can also customize the operating parameter scheme of the piston pump for customers according to the depth of the oil well and the viscosity of crude oil. From equipment selection to on-site commissioning, we provide support throughout the process, so that the operating advantages of API 11AX Tubing Pump can be fully utilized to help oil fields achieve stable and efficient crude oil extraction.